Linear and Torque motor solutions

We direct drive your motion technology

Direct drive technology is a perfect way to enhance productivity, accuracy and dynamic performance. Torque and linear motors make application designs slimmer, modular and reduces costs.

A unique range of precision Linear Stage solutions, multi-axis linear stages, linear stages and gantries.

Gorman Dynamics specializes in providing efficient and reliable engineered products and services for linear stage solutions worldwide. With a strong emphasis on design quality, their line of linear motion products includes Ironless and Iron Core systems, multi-axis solutions, and Gantries. Gorman Dynamics stands out as an exceptional partner in the field of linear motor solutions, known for their capacity for innovation and staying at the forefront of technological advancements. Clients can rely on Gorman Dynamics' expertise and dedication to deliver cutting-edge linear motion solutions for various applications.

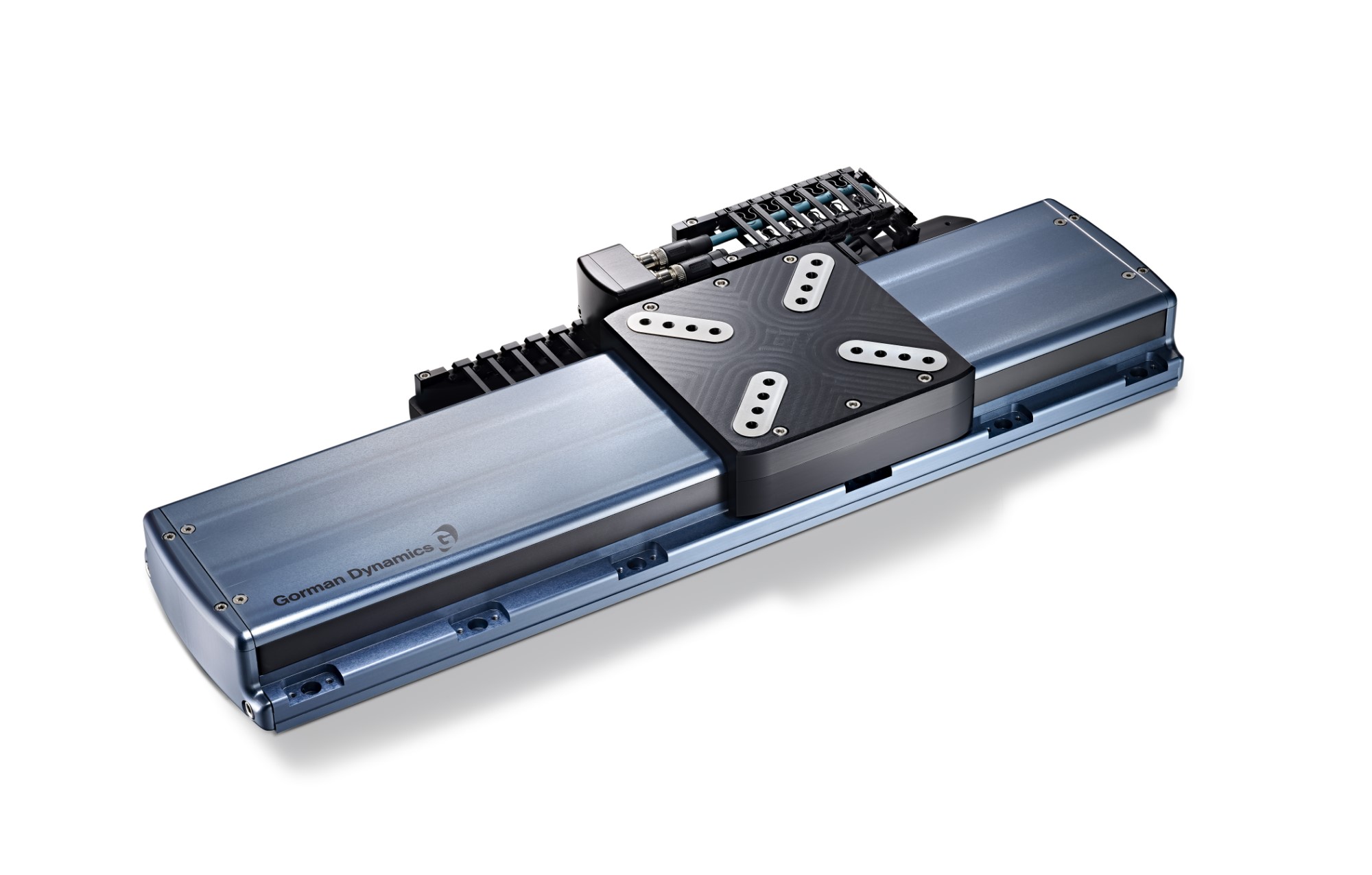

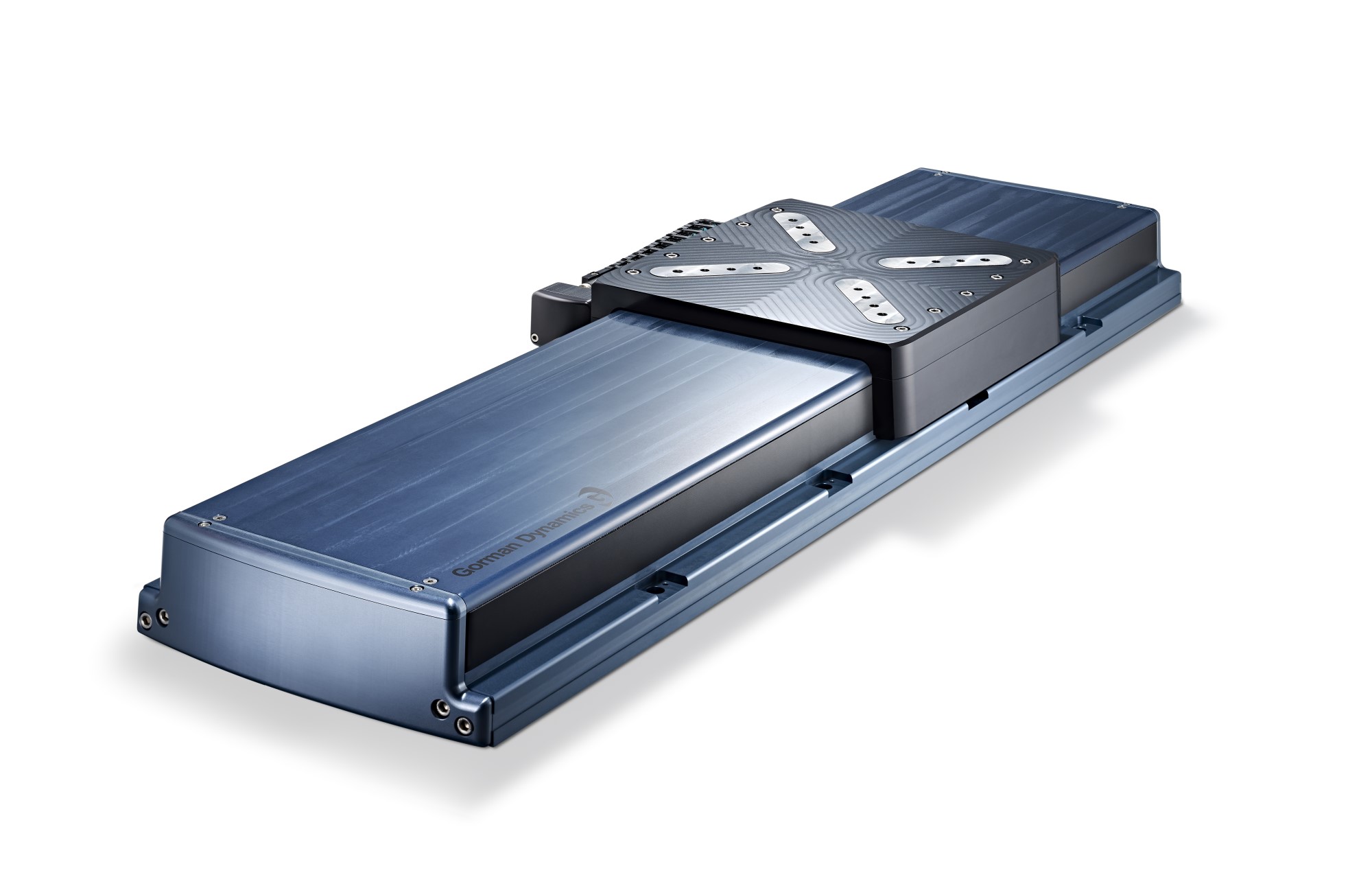

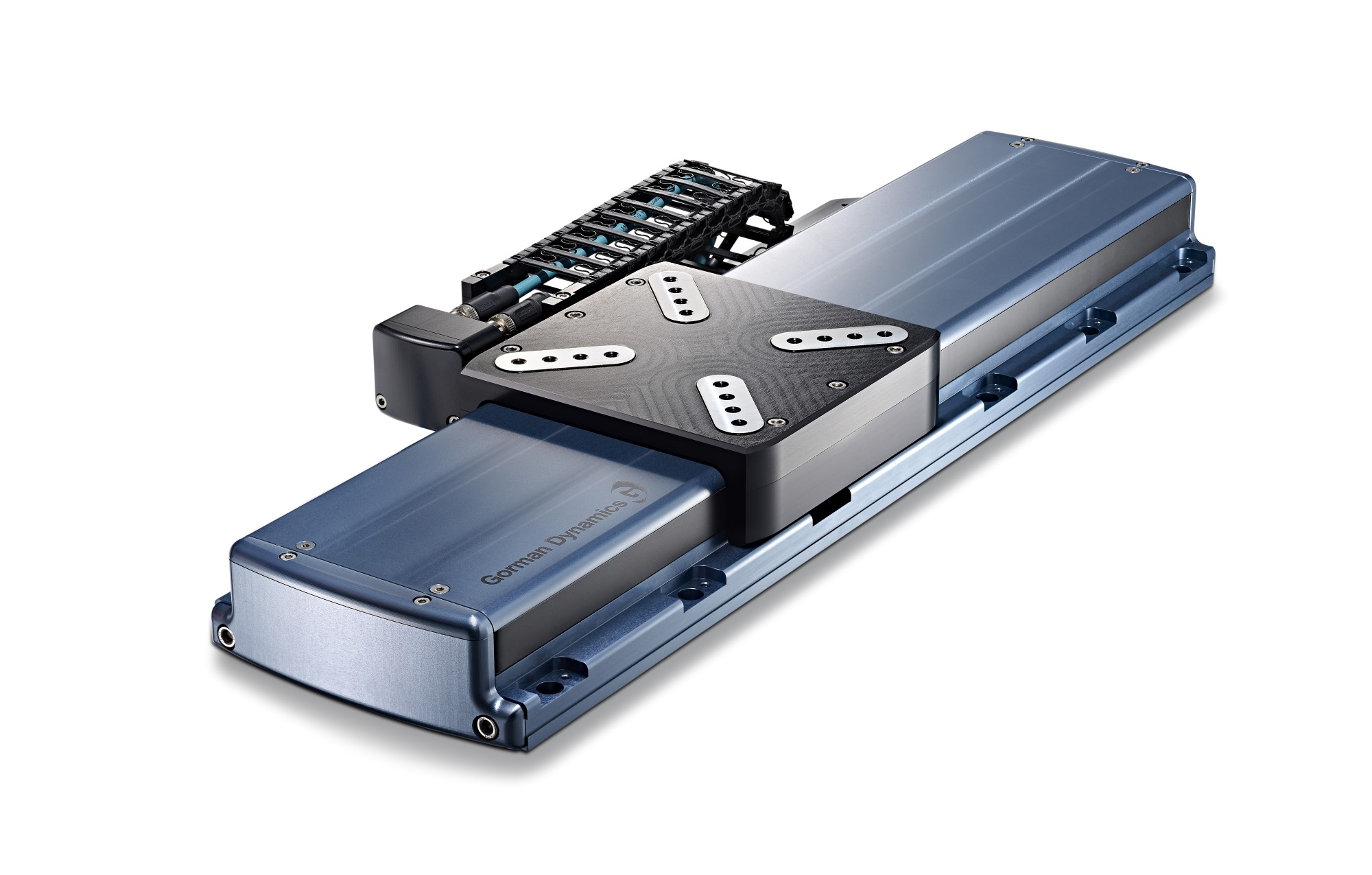

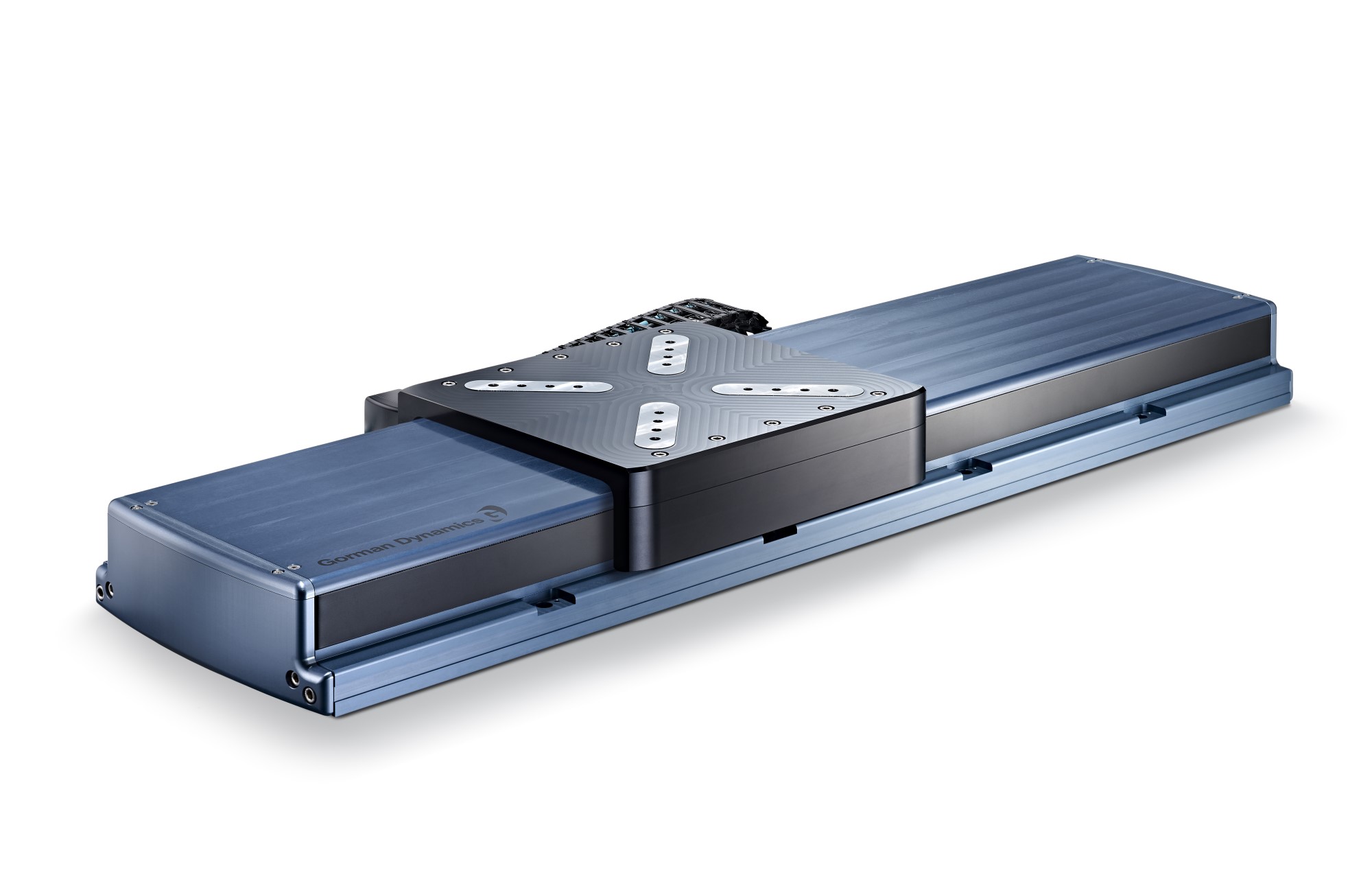

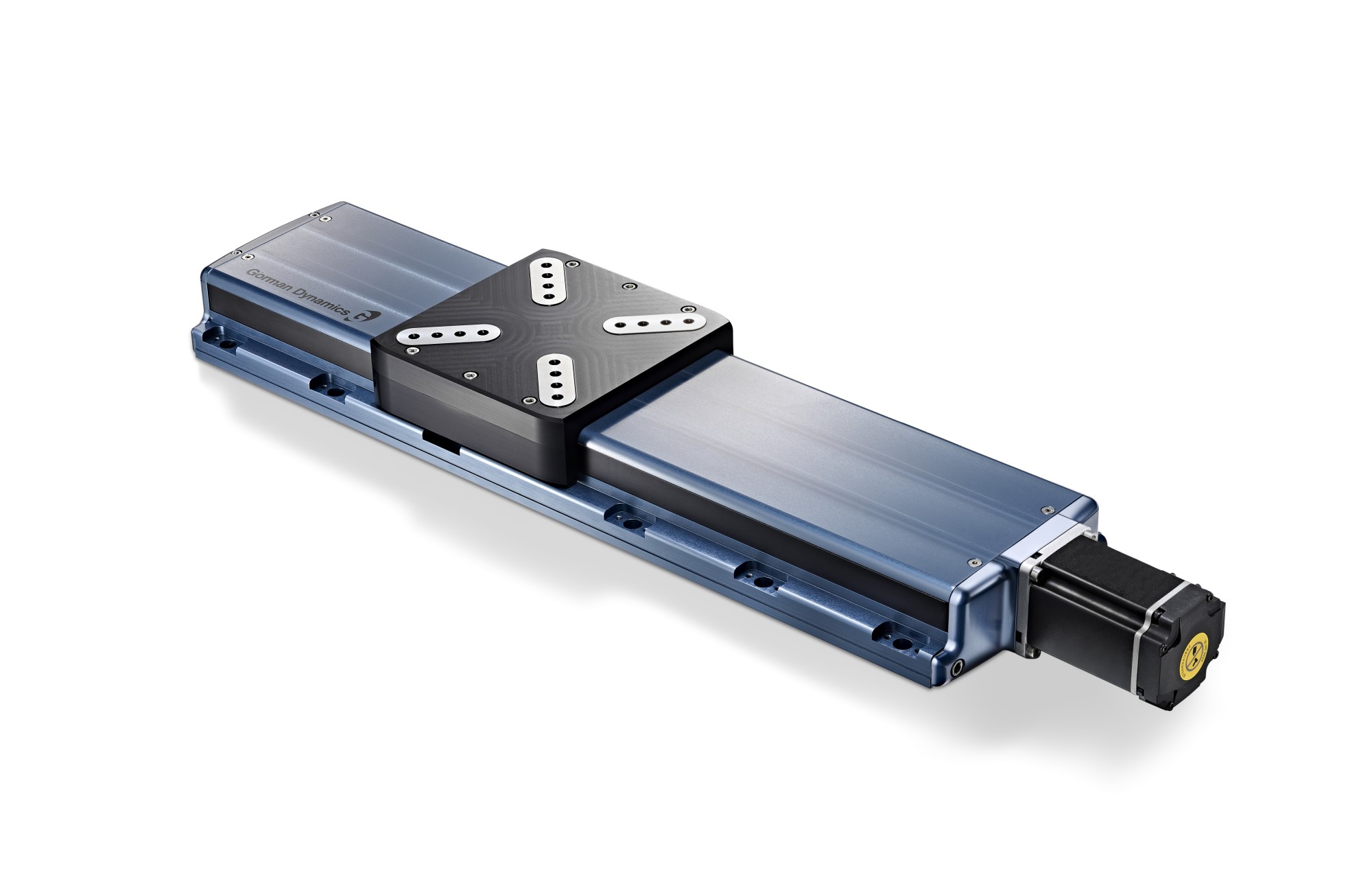

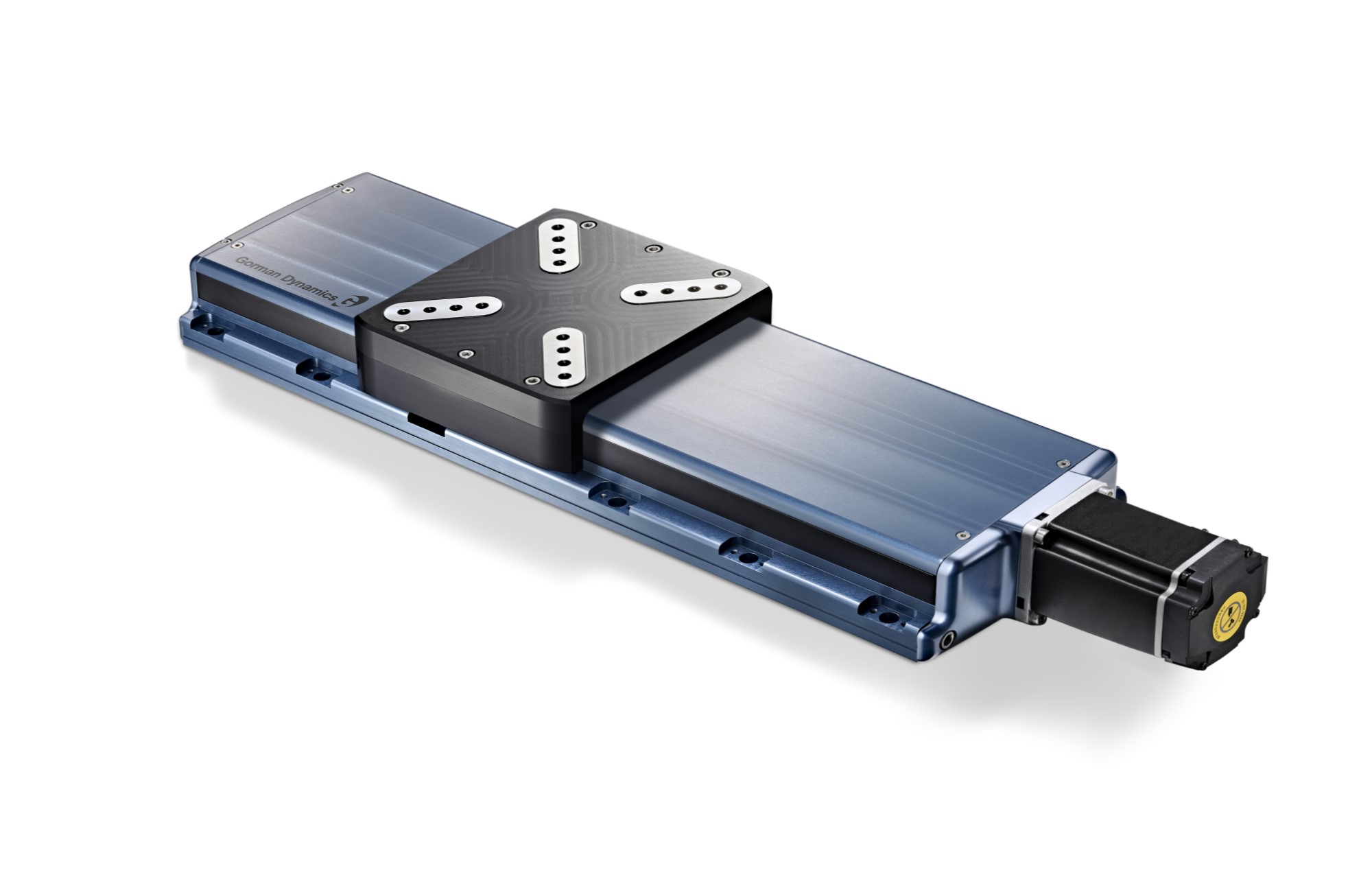

Precision Linear Stages

- Width 115mm

- Travels 50mm to 400mm

- High Load Capacity 45 kg, 450 N

- Speed 2 m/s

- Continuous Force 39 N

- High resolution absolute linear encoder

- Side cover to protect against particles

- Ironless Linear Motor

- Width 165mm

- Travels 100mm to 1200mm

- High Load Capacity 45 kg, 450 N

- Speed 2 m/s

- Continuous Force 58 N

- High resolution absolute linear encoder

- Side cover to protect against particles

- Ironless Linear Motor

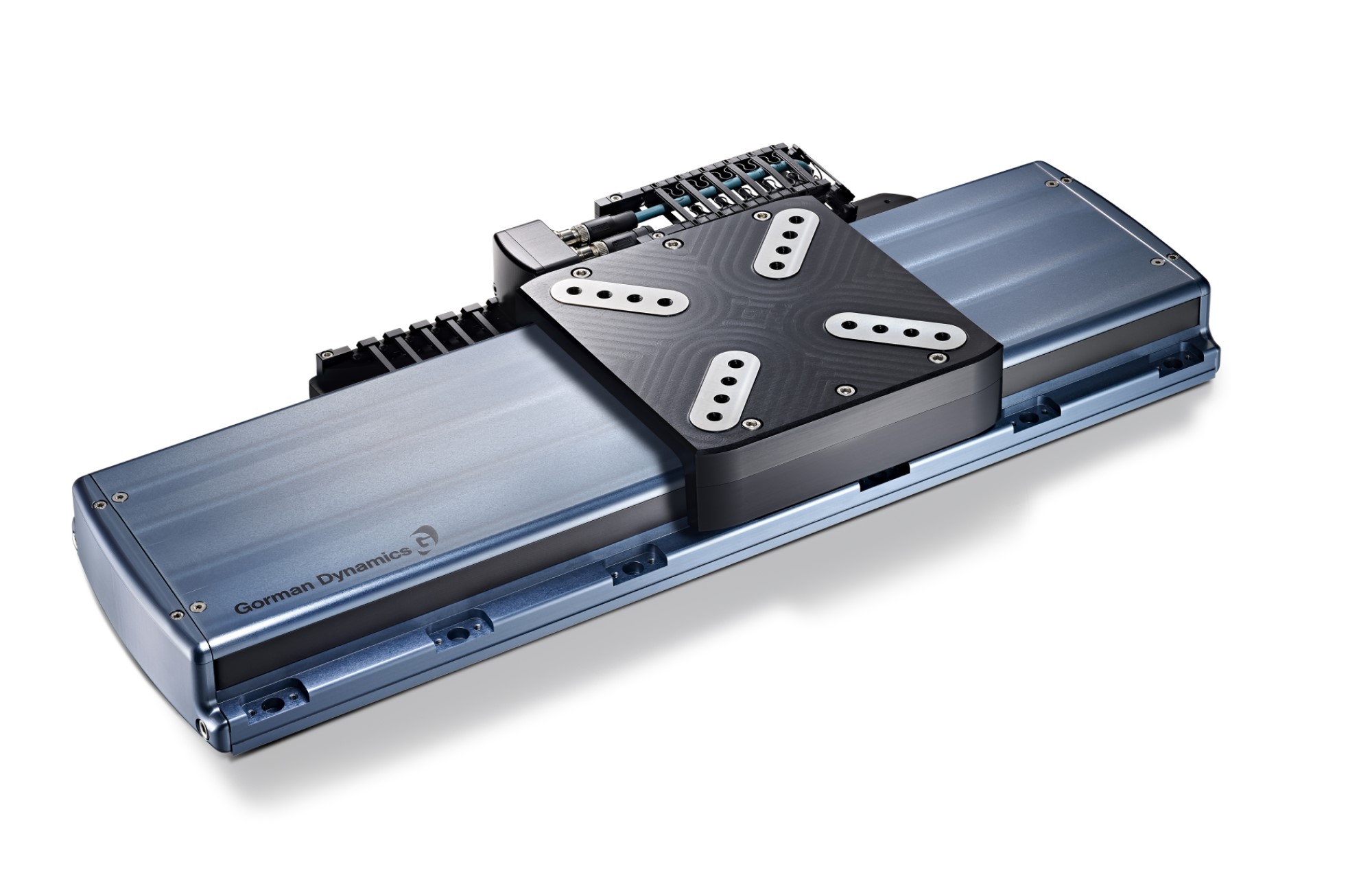

- Width 190mm

- Travels 100mm to 1200mm

- High Load Capacity 80 kg, 800 N

- Speed 2 m/s

- Continuous Force 87 N

- High resolution absolute linear encoder

- Side cover to protect against particles

- Ironless Linear Motor

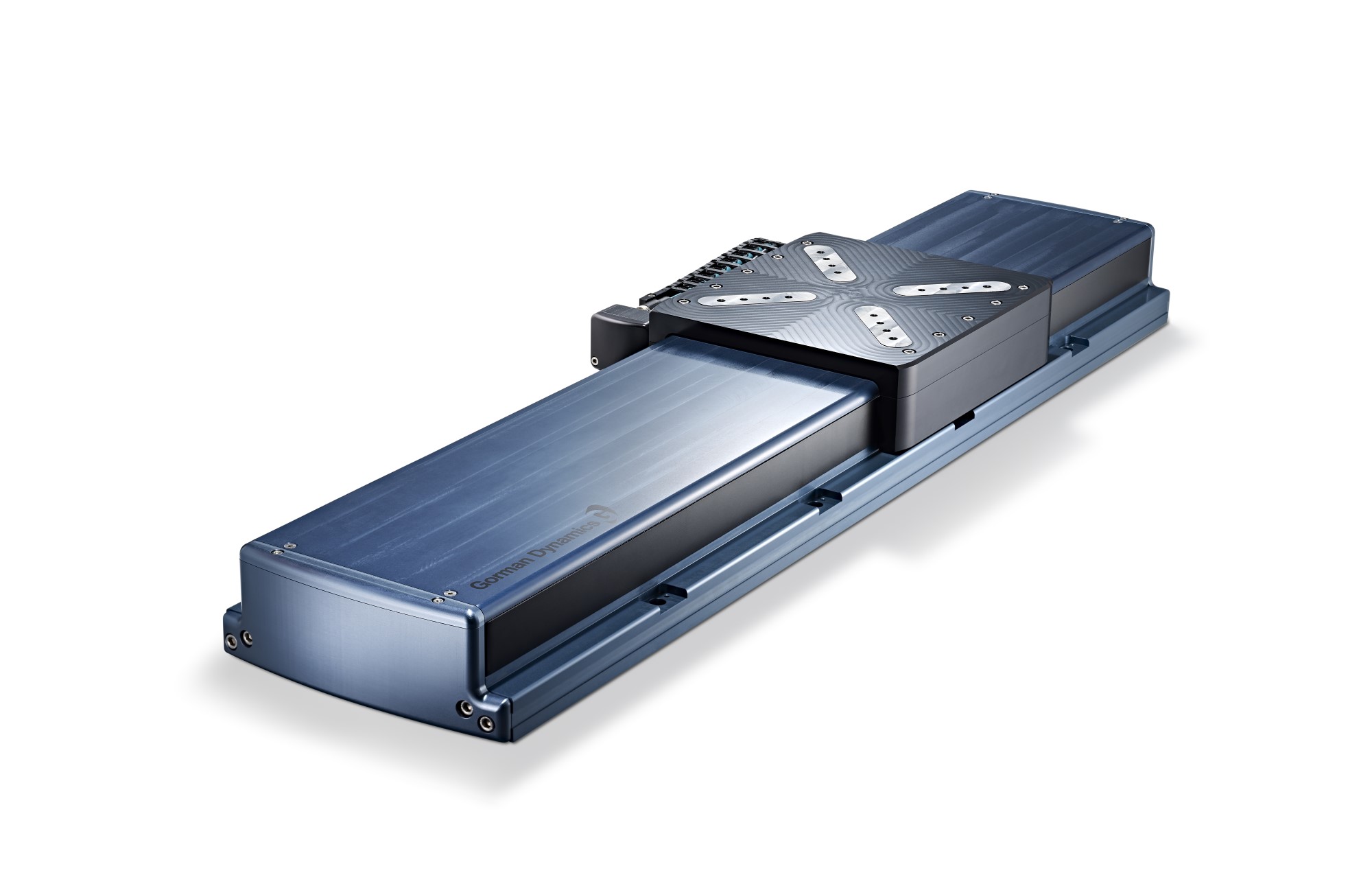

- Width 225mm

- Travels 100mm to 1200mm

- High Load Capacity 120 kg, 1200 N

- Speed 2 m/s

- Continuous Force 140 N

- High resolution absolute linear encoder

- Side cover to protect against particles

- High performance Ironless Linear Motor

- Width 280mm

- Travels 100mm to 1200mm

- High Load Capacity 185 kg, 1850 N

- Speed 2 m/s

- Continuous Force 240 N

- High resolution absolute linear encoder

- Side cover to protect against particles

- High performance Ironless Linear Motor

High Force Precision Linear Stages

- Width 190mm

- Travels 100mm to 1200mm

- High Load Capacity 80 kg, 650 N

- Speed 2 m/s

- Continuous Force 120 N

- High resolution absolute linear encoder

- Side cover to protect against particles

- High performance Iron Core Linear Motor

- Width 225mm

- Travels 100mm to 1200mm

- High Load Capacity 120 kg, 1200 N

- Speed 2 m/s

- Continuous Force 420 N

- High resolution absolute linear encoder

- Side cover to protect against particles

- High performance Iron Core Linear Motor

- Width 280mm

- Travels 100mm to 1200mm

- High Load Capacity 185 kg, 1850 N

- Speed 2 m/s

- Continuous Force 1140 N

- High resolution absolute linear encoder

- Side cover to protect against particles

- High performance Iron Core Linear Motor

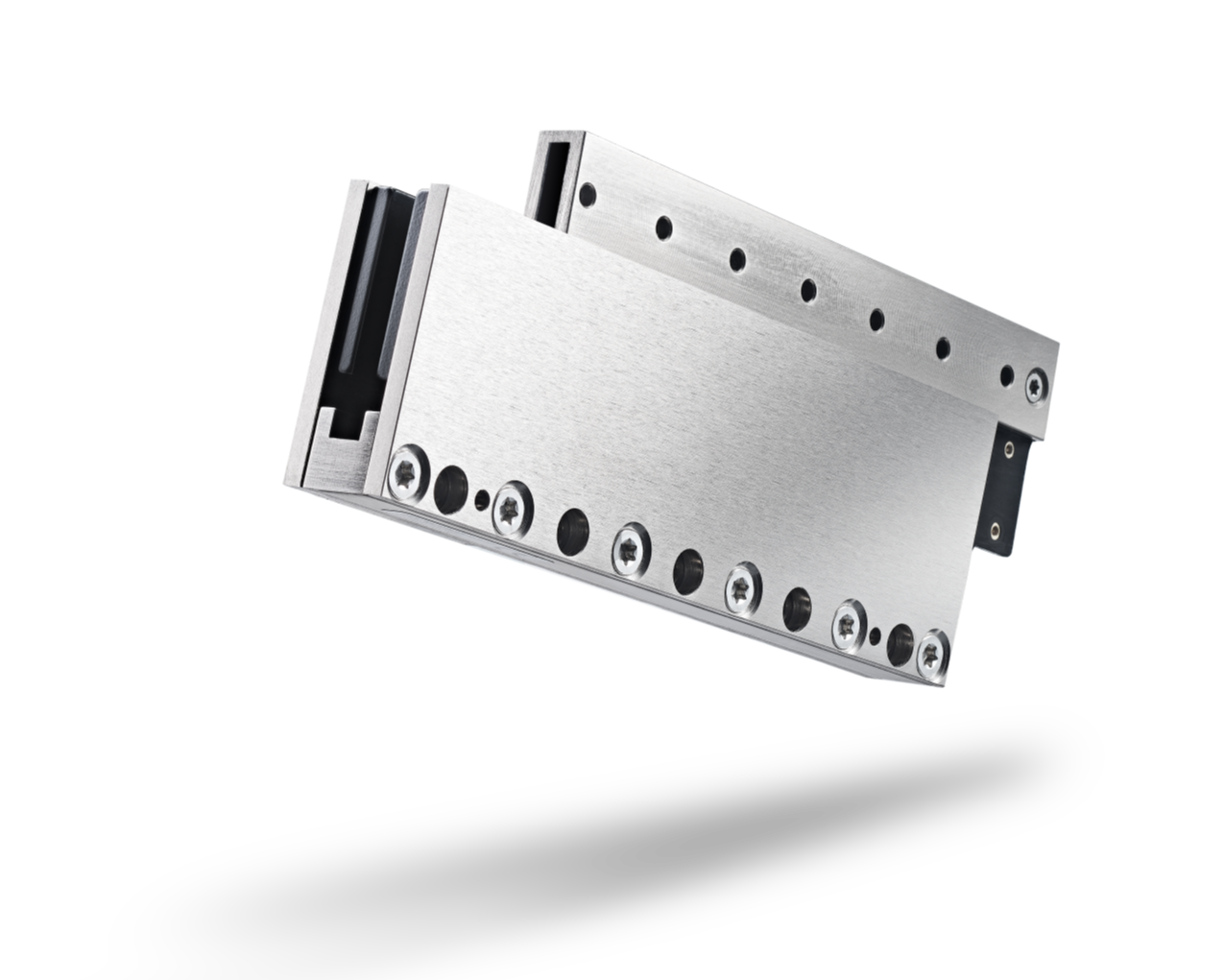

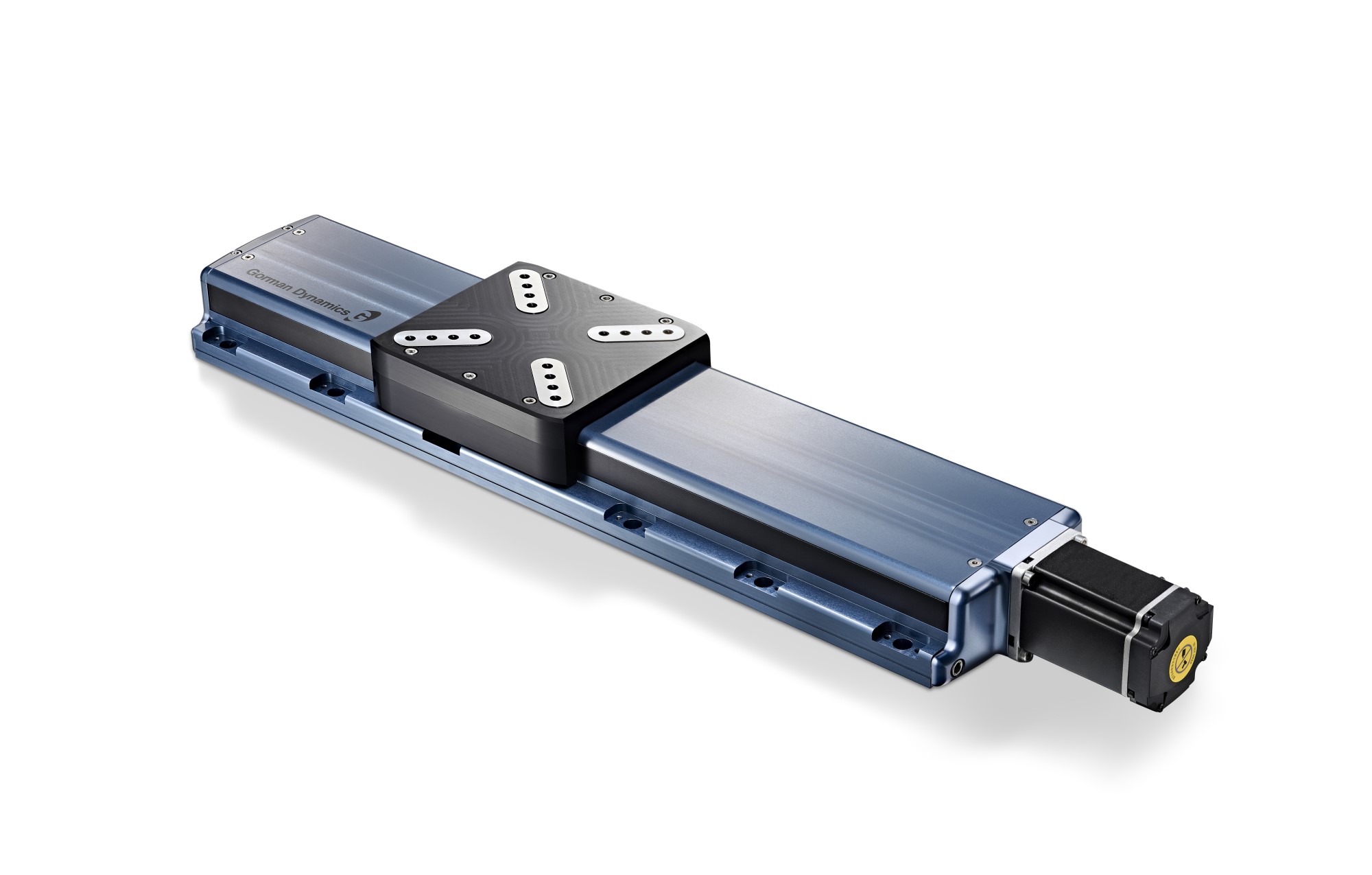

Precision Ball-Screw Stages

- Width 115mm

- Travels 50mm to 400mm

- High Load Capacity 42 kg, 450 N

- Speed 500 mm/s

- High resolution multi-turn absolute encoder, Incremental - 1024, 2048 and 2500 per rev 1Vpp and TTL

- Side cover to protect against particles

- Drive - precision Ball-Screw

- Width 165mm

- Travels 100mm to 400mm

- High Load Capacity 45 kg, 450 N

- Speed 500 mm/s

- High resolution multi-turn absolute encoder, Incremental - 1024, 2048 and 2500 per rev 1Vpp and TTL

- Side cover to protect against particles

- Drive - precision Ball-Screw

- Width 190mm

- Travels 100mm to 1200mm

- High Load Capacity 80 kg, 800 N

- Speed 500 mm/s

- High resolution multi-turn absolute encoder, Incremental - 1024, 2048 and 2500 per rev 1Vpp and TTL

- Side cover to protect against particles

- Drive - precision Ball-Screw

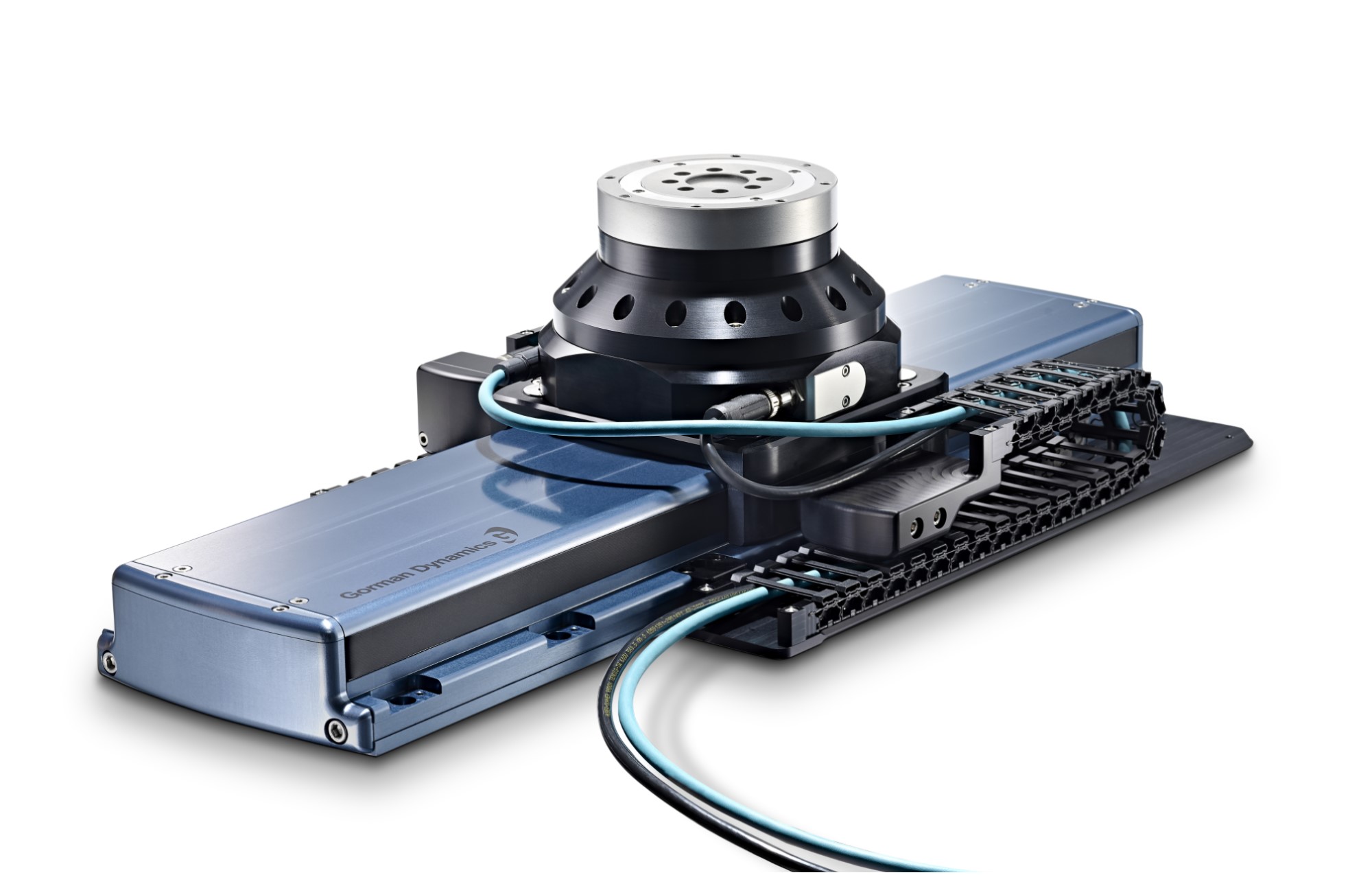

Precision Rotary Stages

- Direct drive rotary

- Load Capacity 26 kg

- Stiff high precision cross roller bearings

- High resolution absolute multi-turn rotary encoders

- Max speed - 1500 (rpm) (endless)

- Maximum torque 7.57 (Nm)

- Direct drive tilt rotary

- Counter balanced

- Load Capacity 18 kg

- Stiff high precision cross roller bearings

- High resolution absolute multi-turn rotary encoders

- Max speed - Tilt 720 (°/sec) (=/- °180)

- Max speed - Yaw 1150 (rpm) (endless)

- Maximum torque 7.57 (Nm)

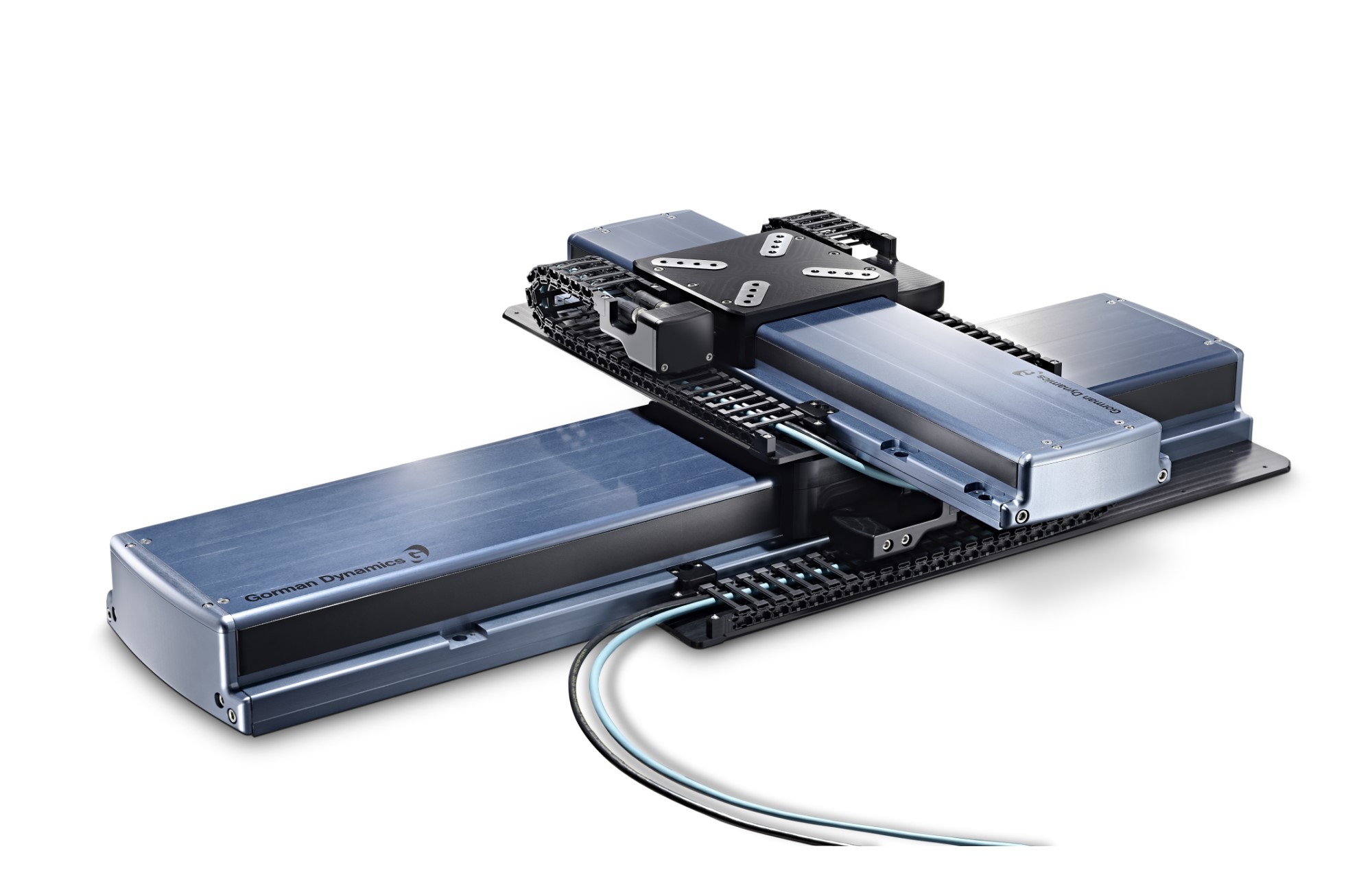

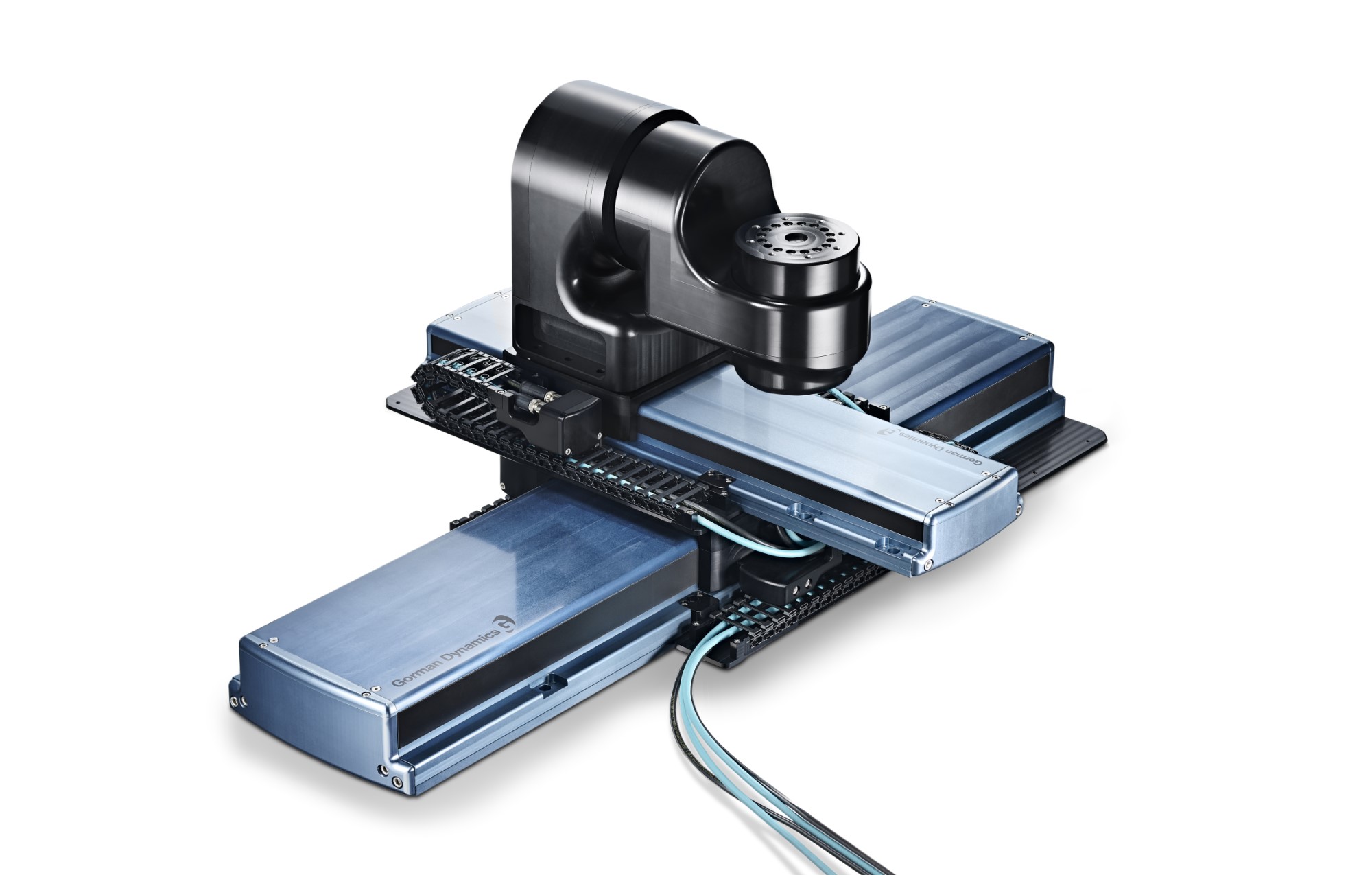

Multi-Axis Linear Stages

- X & Y Axis - Travel 100mm to 1200mm

- High resolution absolute linear encoder

- High Load Capacity 40 kg, 400 N

- Speed 2 m/s

- Side cover to protect against particles

- Ironless Linear Motor

- Travel 100mm to 1200mm

- Theta - Direct Drive, Endless

- High resolution absolute linear encoder

- High resolution absolute multi-turn encode

- High Load Capacity 40 kg, 400 N

- Speed 2 m/s

- Side cover to protect against particles

- Ironless Linear Motor

- X & Y Axis - Travel 100mm to 1200mm

- Theta - Direct Drive, Endless

- High resolution absolute linear encoder

- High resolution absolute multi-turn encode

- High Load Capacity 40 kg, 400 N

- Speed 2 m/s

- Side cover to protect against particles

- Ironless Linear Motor

- X & Y Axis - Travel 100mm to 1200mm

- High resolution absolute linear encoder

- Speed 2 m/s

- Side cover to protect against particles

- Ironless Linear Motor

- Direct drive tilt rotary

- Counter balanced

- Load Capacity 18kg

- Stiff high precision cross roller bearings

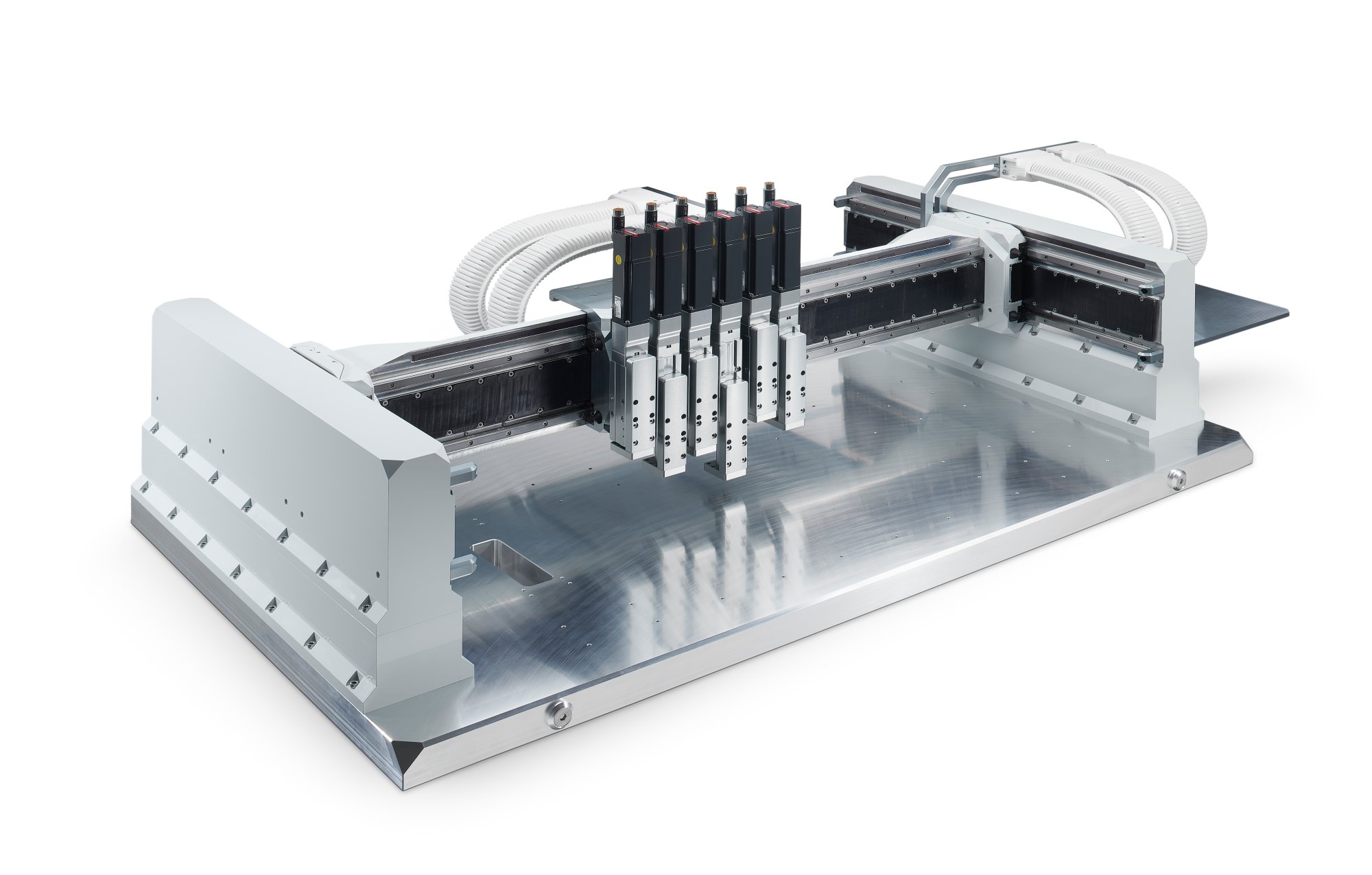

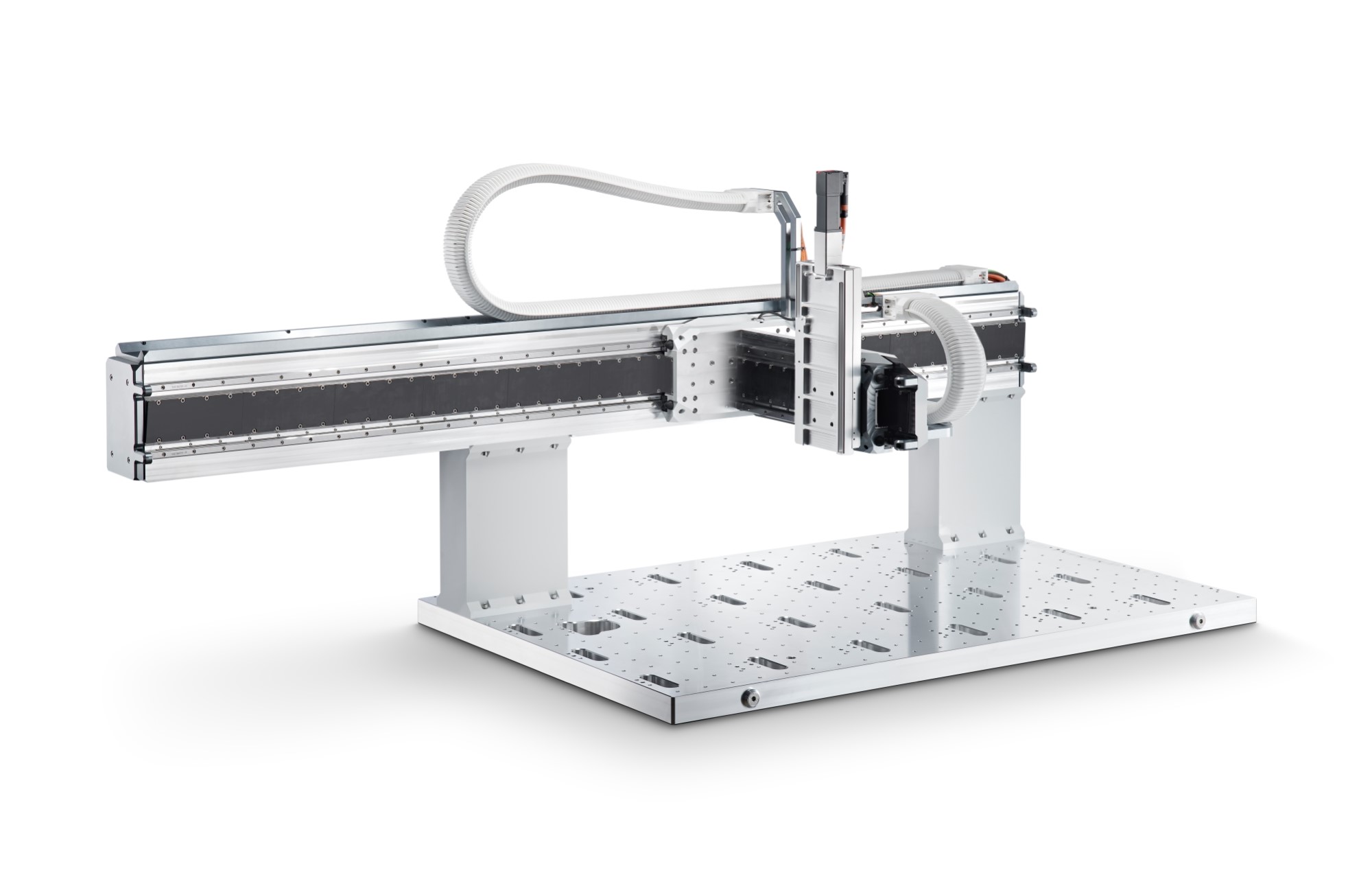

Linear Gantry Solutions - Demanding applications

- Travel 300mm to 1400mm - Fixed Y Axis

- Multi Gantries on Y Axis

- 2 Motors per moving Gantry

- Travel 300mm to 1400mm - Moving Gantry X Axis

- Multi Carriage Movers on Gantry Axis

- High Load Capacity per Carriage 50 kg, 500 N

- Speed 3 m/s

- High resolution absolute linear encoder

- Iron Core Liner Motors

- Travel 200mm to 1600mm - Fixed X Axis

- Multi Gantries on X Axis

- Travel 200mm to 600mm - Moving Gantry Y Axis

- Multi Carriage Movers on Gantry Axis

- High Load Capacity per Carriage 25 kg, 250 N

- Speed 4 m/s

- High resolution absolute linear encoder

- Iron Core Liner Motors

- Travel up to 5700mm - Fixed X Axis

- Multi Gantries on X Axis

- Travel up to 2800mm - Moving Gantry Y Axis

- Multi Carriage Movers on Gantry Axis

- High Load Capacity per Carriage 225 kg, 2250 N

- Speed 3.5 m/s

- High resolution absolute linear encoder

- Iron Core Liner Motors

Automation Projects and Services - Factory 4.0

Customized motion solutions available for all Linear stage products. Our dedicated team is available to assist you in delivering a comprehensive solution that precisely aligns with your unique performance specifications.

Gorman Dynamics specializes in delivering bespoke automation solutions that are innovatively designed and manufactured to suit the exact needs of our clients.

Ask An Engineer!

Quickly receive an answer to your question from a Gorman Dynamics engineer.

English

English

Español

Español

Français

Français

Deutsch

Deutsch

Svenska

Svenska

한국어

한국어

日本語

日本語