Product Description

Positioning Linear Stage

The Gorman Dynamics TH35 160 Precision Rotary Position Stage is an advanced direct-drive solution known for its high-precision and stiff construction. Equipped with cross roller bearings, it offers exceptional stability and rigidity, ensuring minimal flex and precise angular positioning. The direct-drive technology guarantees excellent dynamic response with no backlash. With its compact size and high torque capacity, this stage is well-suited for applications that require precise rotary motion control, such as optics, metrology, and automated testing. Count on Gorman Dynamics for reliable and precise rotary position stages with robust cross roller bearing construction.

Direct Drive Torque Motor

Utilizing torque motors in various applications offers several advantages. Firstly, their direct-drive nature eliminates the need for additional components like transmissions or gearboxes, reducing complexity, costs, and maintenance. With no mechanical contact between the rotor and stator, torque motors eliminate mechanical wear, resulting in longer lifespan and lower maintenance requirements. Their high torque density and smooth motion allow for precise and dynamic control. Additionally, torque motors exhibit high efficiency, low vibration, and excellent responsiveness, making them ideal for applications that demand high accuracy, reliability, and optimal performance.

Applications for Rotary Stages

Precision rotary stages find diverse applications across multiple industries. They are widely used in optics and photonics for precise angular positioning, such as beam steering, polarization control, and alignment of optical components. In the manufacturing sector, precision rotary stages enable precise indexing, machining, and assembly operations. They also play a crucial role in metrology, where accurate angular measurements are required. Additionally, precision rotary stages find applications in robotics, aerospace, medical device manufacturing, and research laboratories. Their versatility and precise motion control make them indispensable in industries that demand accurate and controlled rotational movements.

Specifications TH35-x

| TH35 Series | TH35-160 | ||||

| Rotating Face diameter (mm) | 115 | ||||

| Position Accuracy uncalibrated (arc sec) | ±20 | ||||

| Position Accuracy calibrated (arc sec) | ±2.5 | ||||

| Resolution System (arc sec) | 0.02 | ||||

| Repeatability Bi-directional (arc sec) | ±1.5 | ||||

| Max Axial Load (kg) | 26 | ||||

| Max Radial Load (kg) | 14 | ||||

| Error Axial Motion (um) | 2 | ||||

| Error Radial Motion (um) | 3 | ||||

| Error Tilt Motion (arc sec) | 8 | ||||

| Maximum Velocity No Load (rpm) | 1500 | ||||

| Nominal Force (Nm) | 7.57 | ||||

| Stage Weight (kg) | 3.6 |

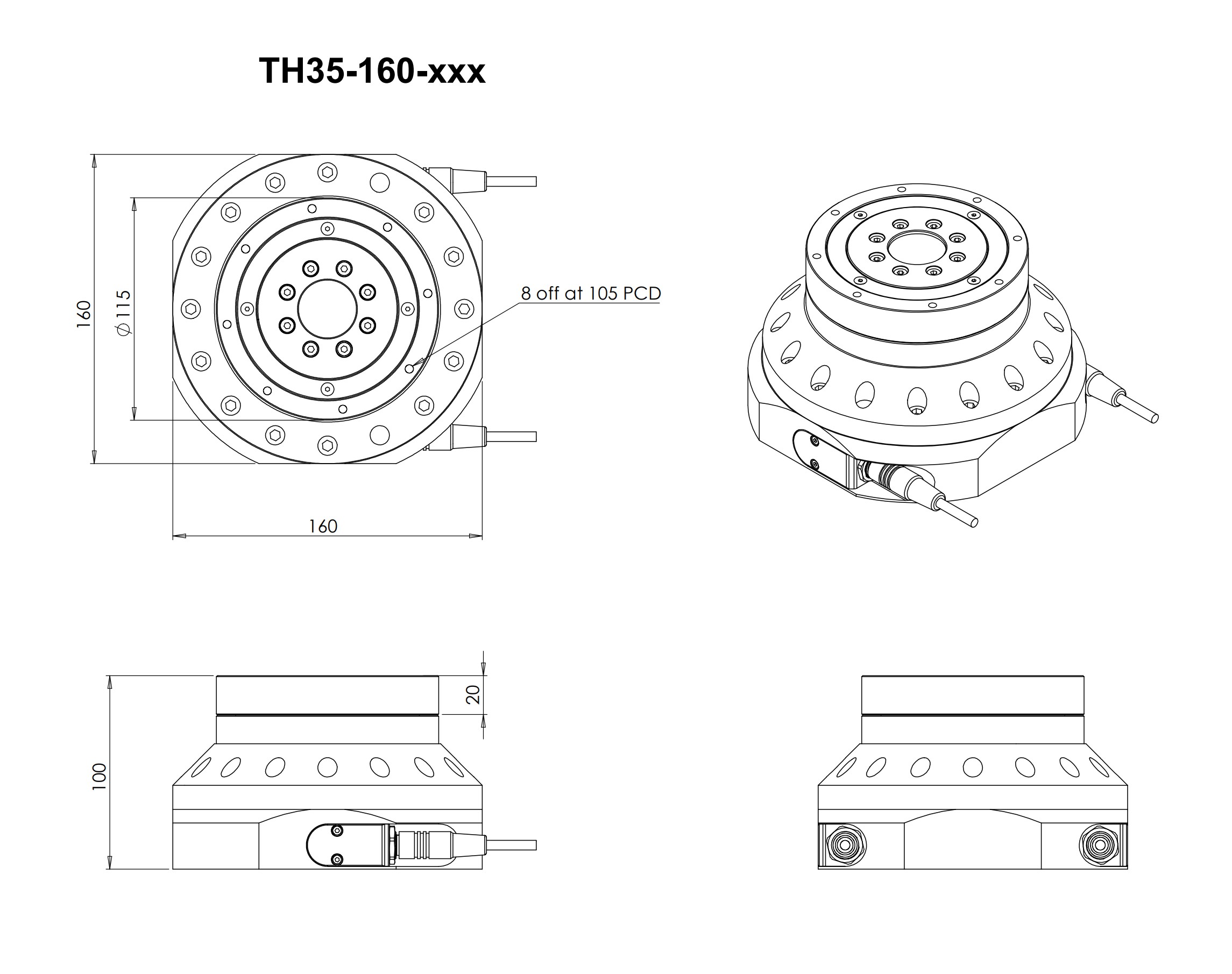

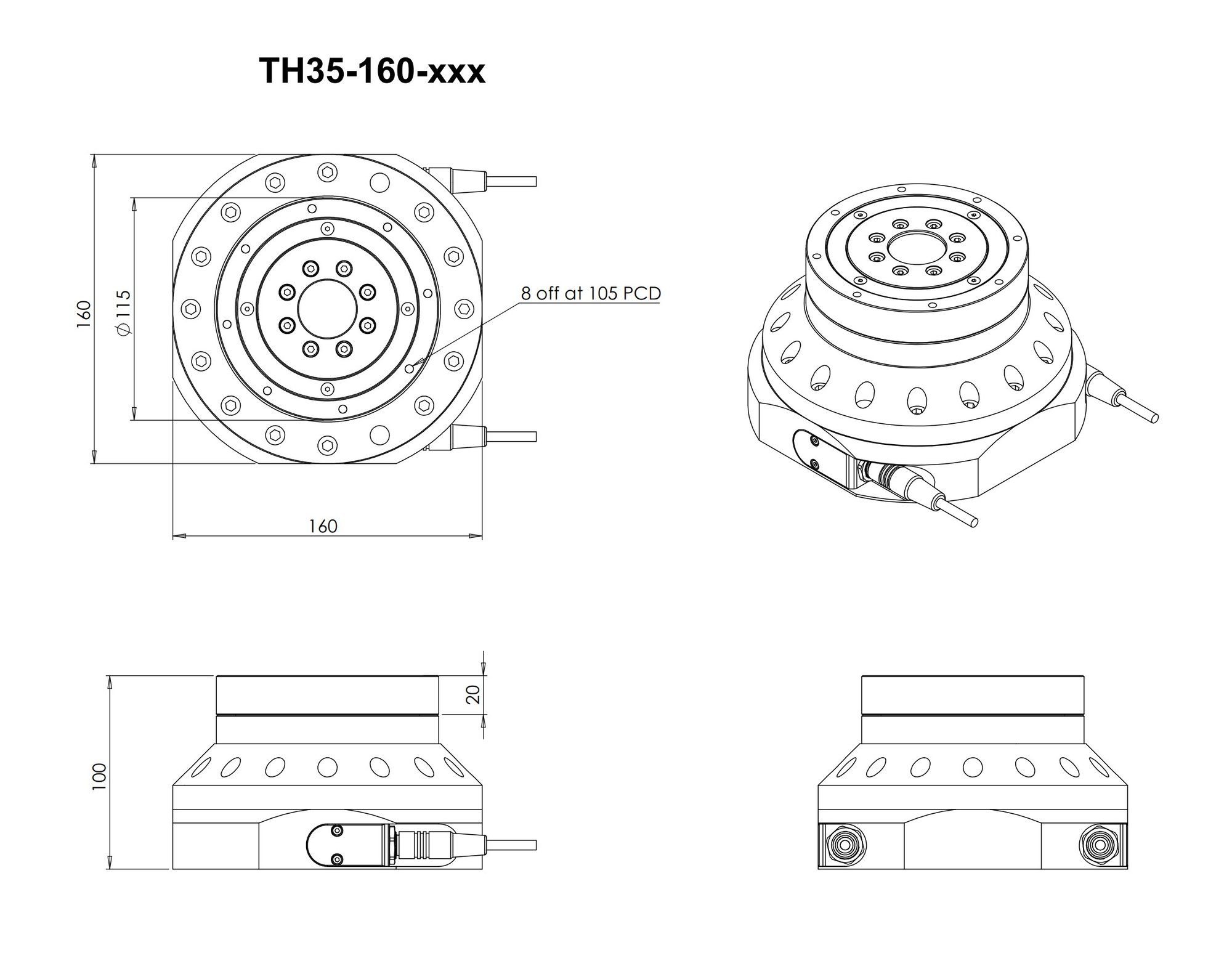

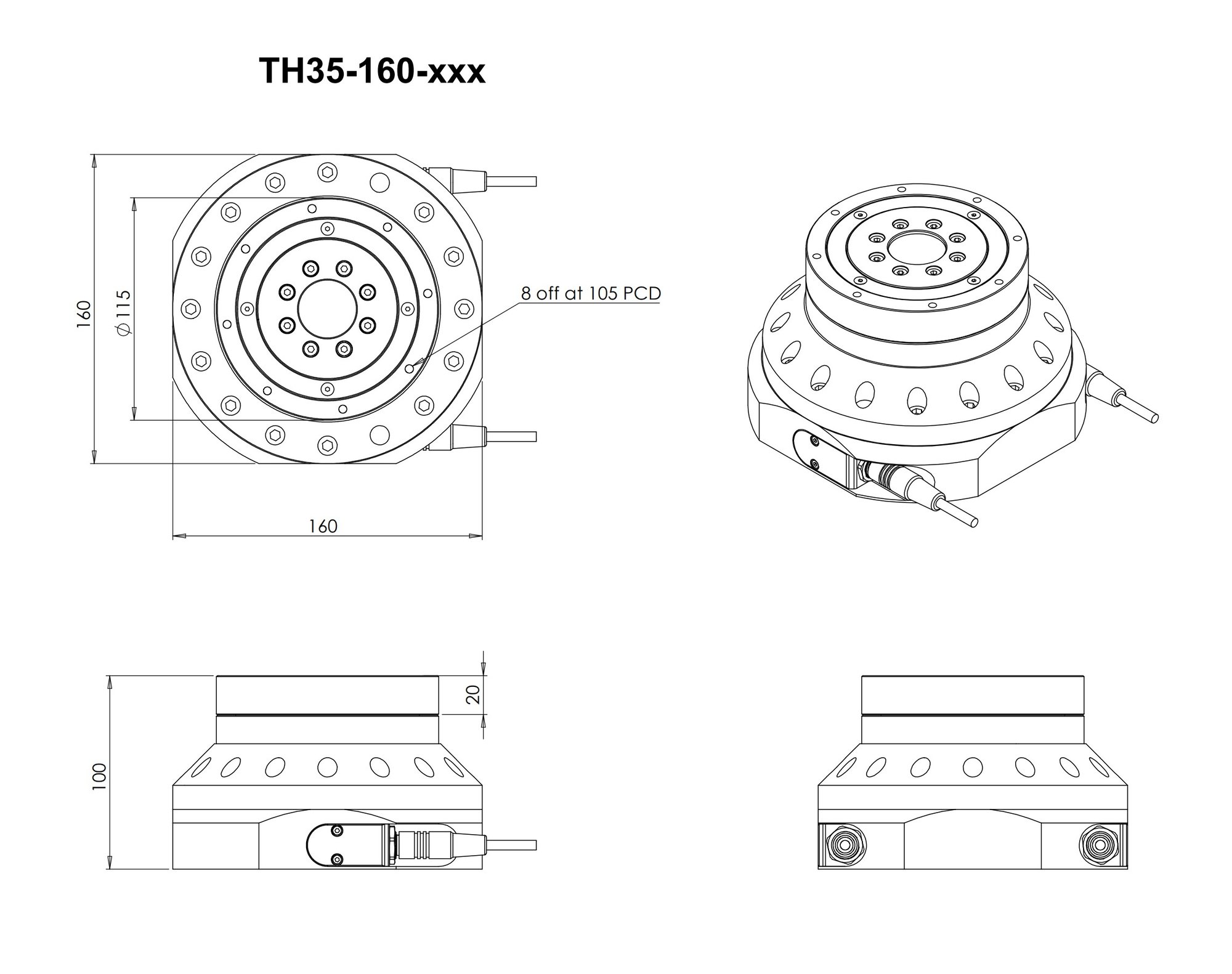

Product Dimensions

Ask An Engineer!

Quickly receive an answer to your question from a Gorman Dynamics engineer.

Related Products

- Direct drive tilt rotary

- Counter balanced

- Load Capacity 18 kg

- Stiff high precision cross roller bearings

- High resolution absolute multi-turn rotary encoders

- Max speed - Tilt 720 (°/sec) (=/- °180)

- Max speed - Yaw 1150 (rpm) (endless)

- Maximum torque 7.57 (Nm)

English

English

Español

Español

Français

Français

Deutsch

Deutsch

Svenska

Svenska

한국어

한국어

日本語

日本語