Custom Linear Stages

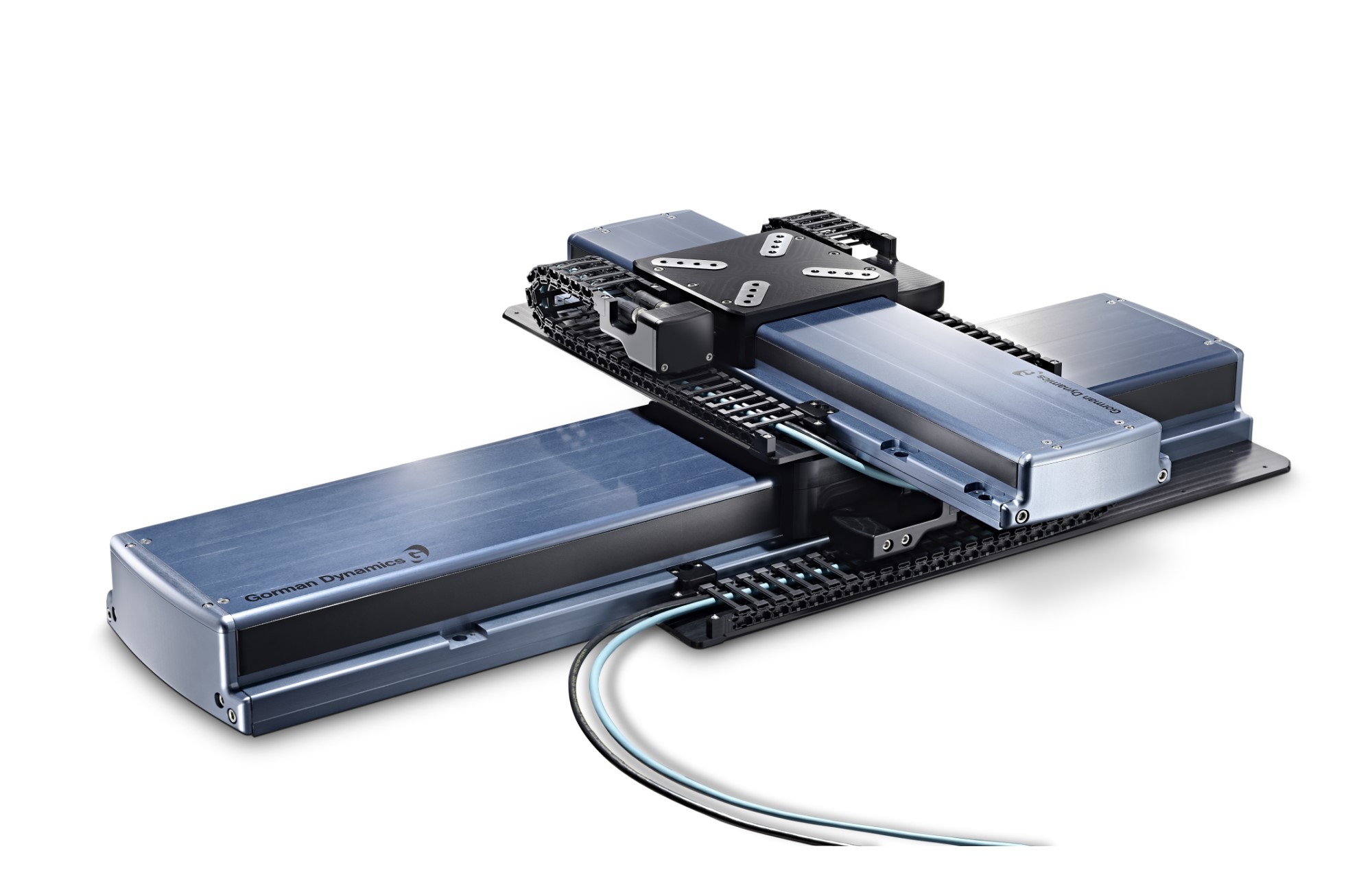

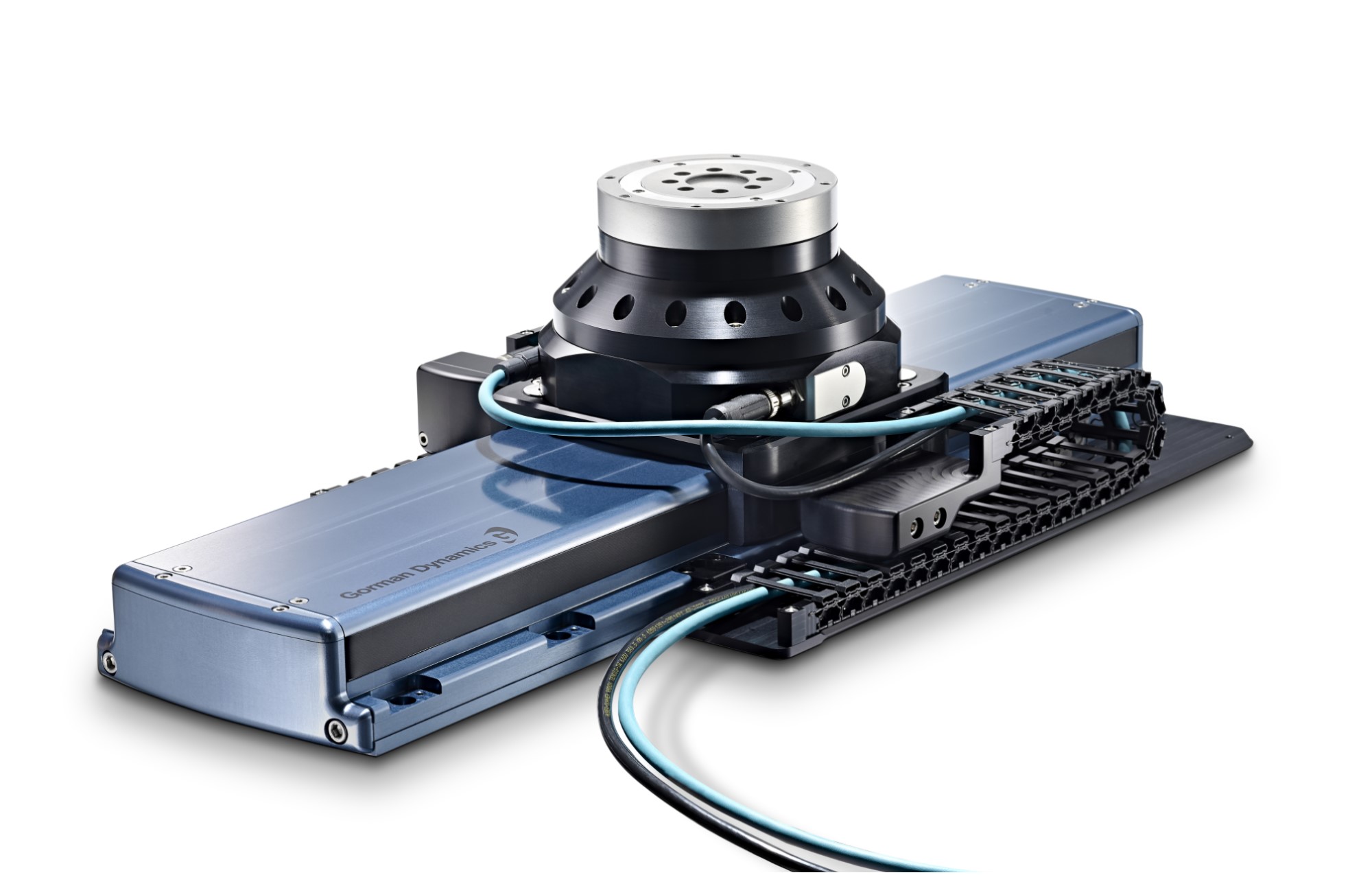

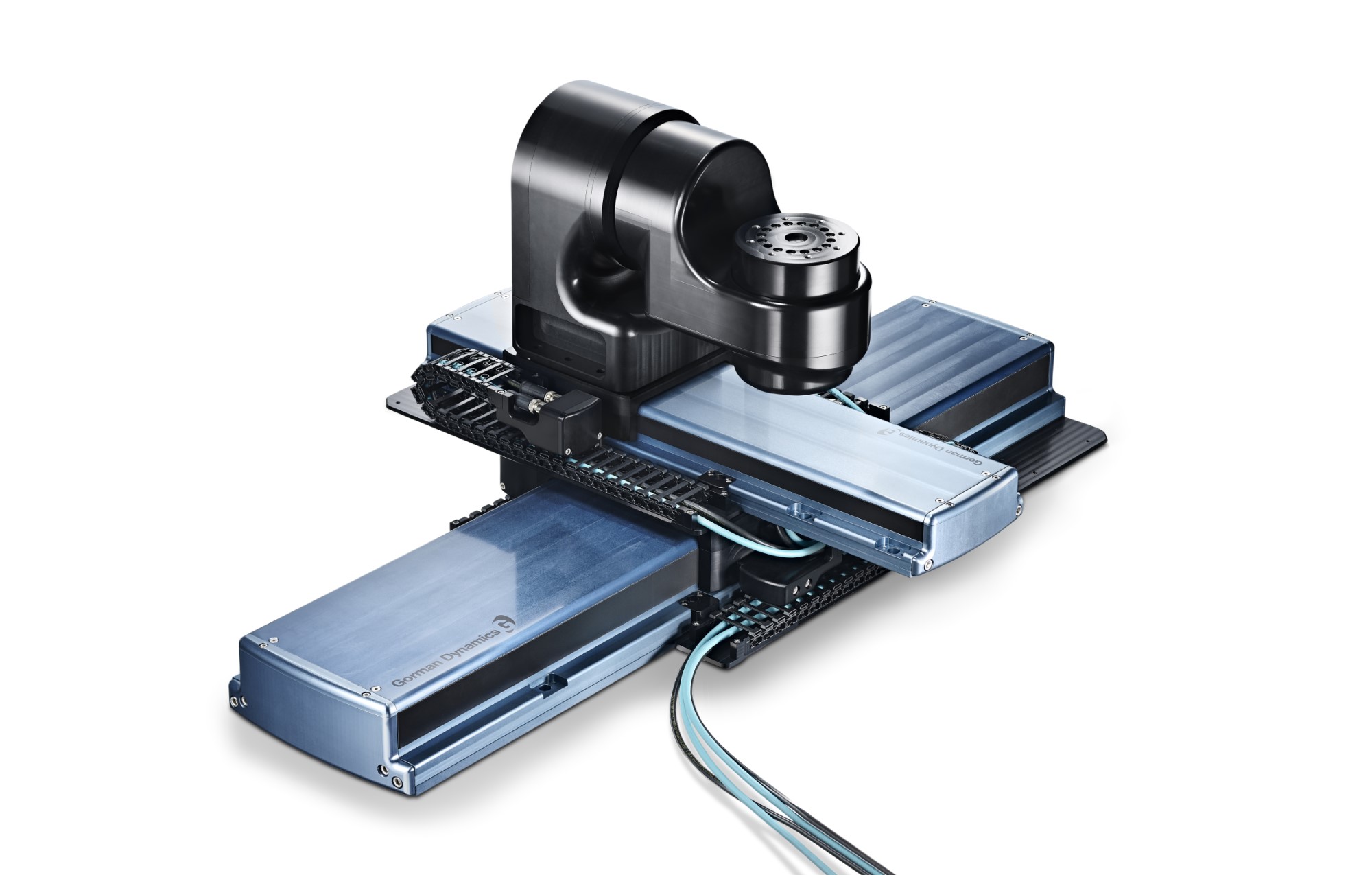

XY Linear Stages + Theta

An XY linear stage combined with a theta stage offers precise motion control in both linear and angular directions. This configuration enables accurate positioning and orientation adjustments in two dimensions, making it ideal for applications that require precise linear movements along with rotational adjustments, such as optical systems, robotics, and automated assembly processes.

XY Precision Ironless Stages combined with Rotary Theta Stage

Customised Linear Stage Solutions

Gorman Dynamics specializes in supplying multi-axis precision stages tailored to suit your specific needs. Our extensive range of precision stages includes XY stages, XYZ stages, theta stages, and custom multi-axis configurations. These stages are designed to deliver exceptional accuracy, repeatability, and smooth motion control, ensuring precise positioning in a wide range of applications. Whether you require high-speed scanning, precise alignment, or complex multi-axis movements, our precision stages offer reliable and efficient solutions. Contact us today to discuss your requirements and benefit from our expertise in providing customized multi-axis precision stages for your unique application needs.

Linear Stage XY

A linear stage XY refers to a positioning system that enables precise movement in both the X and Y directions. It provides accurate and controlled motion along two perpendicular axes, allowing for precise positioning and alignment in various applications. Linear stage XY systems are widely used in fields such as semiconductor manufacturing, microscopy, laser processing, and research laboratories. They offer high accuracy, repeatability, and smooth motion, making them essential for tasks that require precise positioning, scanning, or automated operations.

Theta Stage

A theta stage, also known as a rotary stage, is a positioning system designed to provide precise rotational motion around a central axis. It allows for accurate angular positioning and rotation control, typically in applications that require precise alignment or orientation changes. Theta stages are commonly used in fields such as optics, metrology, robotics, and precision machining. They offer high accuracy, smooth rotation, and repeatable performance, making them ideal for tasks that involve scanning, indexing, optical component alignment, or angular measurements. Theta stages are crucial for achieving precise angular control and rotational movements in various applications.

Integrated Cable Management

Our multi-axis stages are supplied with robust integrated cable management. These stages are designed to provide precise and coordinated motion in multiple axes, enabling complex positioning and alignment tasks. With our integrated cable management systems, cables are securely routed and organized, minimizing clutter and potential damage. This enhances system reliability, simplifies installation, and reduces maintenance efforts. Experience the convenience and reliability of multi-axis stages with robust integrated cable management.

Benefits and Advantages

Precision linear stages offer several key advantages in various applications:

- High Accuracy: Precision linear stages are designed to provide exceptional positioning accuracy, allowing for precise movement and alignment. This accuracy is crucial in applications where precise positioning is required, such as semiconductor manufacturing, microscopy, and optical systems.

- Repeatable Performance: These stages offer excellent repeatability, ensuring consistent and reliable results with each movement. This is essential in applications that require repetitive tasks or precise measurements.

- Smooth Motion: Precision linear stages are engineered to deliver smooth and stable motion, minimizing vibrations and disturbances. This enables the precise handling of delicate objects or the scanning of sensitive surfaces.

- Flexibility and Customization: These stages can be customized to meet specific application requirements, such as travel range, load capacity, and mounting options. This versatility allows for seamless integration into various setups and ensures optimal performance.

- High Load Capacity: Precision linear stages are designed to handle substantial loads while maintaining accuracy and stability. This capability is crucial in applications involving heavy equipment or components.

- Durability and Longevity: Built with high-quality materials and advanced engineering, precision linear stages are designed for long-lasting performance, even in demanding environments. This ensures a reliable and durable solution for critical applications.

By leveraging the advantages of precision linear stages, industries can achieve precise and accurate positioning, leading to improved efficiency, enhanced quality, and increased productivity in a wide range of applications.

Linear Stage Applications

- Semiconductor manufacturing: Precision linear stages are essential for wafer handling, alignment, and inspection processes in semiconductor manufacturing.

- Microscopy: These stages enable precise sample positioning and scanning in microscopy applications, facilitating high-resolution imaging and analysis.

- Optical systems: Precision linear stages are utilized in optical systems for lens positioning, beam alignment, and fine-tuning optical setups.

- Metrology: These stages play a crucial role in metrology equipment for precise measurement, calibration, and dimensional analysis.

- Laser processing: Precision linear stages assist in laser cutting, engraving, and micromachining applications, ensuring accurate material processing and positioning.

- Research laboratories: Precision stages find applications in various research fields, such as materials science, nanotechnology, and biotechnology, for precise sample manipulation and experimentation.

- Robotics: Precision linear stages are utilized in robotics for accurate positioning, assembly, and automation tasks.

- Medical devices: These stages are crucial in medical device manufacturing, including implantable devices, robotics-assisted surgery, and diagnostics, ensuring precise movement and positioning.

Related Products

- X & Y Axis - Travel 100mm to 1200mm

- High resolution absolute linear encoder

- High Load Capacity 40 kg, 400 N

- Speed 2 m/s

- Side cover to protect against particles

- Ironless Linear Motor

- Travel 100mm to 1200mm

- Theta - Direct Drive, Endless

- High resolution absolute linear encoder

- High resolution absolute multi-turn encode

- High Load Capacity 40 kg, 400 N

- Speed 2 m/s

- Side cover to protect against particles

- Ironless Linear Motor

- X & Y Axis - Travel 100mm to 1200mm

- High resolution absolute linear encoder

- Speed 2 m/s

- Side cover to protect against particles

- Ironless Linear Motor

- Direct drive tilt rotary

- Counter balanced

- Load Capacity 18kg

- Stiff high precision cross roller bearings

Ask An Engineer!

Quickly receive an answer to your question from a Gorman Dynamics engineer.

English

English

Español

Español

Français

Français

Deutsch

Deutsch

Svenska

Svenska

한국어

한국어

日本語

日本語