GXR 120 Precision 2 Axis Rotary Stage

Direct Drive Axis Gimble

- Direct drive tilt rotary

- Counter balanced

- Load Capacity 18 kg

- Stiff high precision cross roller bearings

- High resolution absolute multi-turn rotary encoders

- Max speed - Tilt 720 (°/sec) (=/- °180)

- Max speed - Yaw 1150 (rpm) (endless)

- Maximum torque 7.57 (Nm)

Product Description

2 Axis Gimble or 3/4th Axis

A 2-axis gimbal is a versatile motion control system that provides precise rotational movement around two perpendicular axes. It allows for smooth and coordinated adjustments in both pitch and yaw directions, enabling precise orientation control. This configuration is widely used in various applications, including photography and videography stabilization, drone technology, tracking systems, and optical instrument positioning. With its ability to stabilize and control movement in two axes, the 2-axis gimbal offers enhanced flexibility and improved stability for capturing smooth and steady footage or achieving accurate angular adjustments in different industries.

Direct Drive Torque Motor

Utilizing torque motors in various applications offers several advantages. Firstly, their direct-drive nature eliminates the need for additional components like transmissions or gearboxes, reducing complexity, costs, and maintenance. With no mechanical contact between the rotor and stator, torque motors eliminate mechanical wear, resulting in longer lifespan and lower maintenance requirements. Their high torque density and smooth motion allow for precise and dynamic control. Additionally, torque motors exhibit high efficiency, low vibration, and excellent responsiveness, making them ideal for applications that demand high accuracy, reliability, and optimal performance.

Counter balanced Stage

In the laser industry, the counterbalance system plays a vital role in two-axis gimbals used for laser positioning and beam control. It ensures precise weight distribution and stability, enabling accurate alignment of laser beams in both pitch and yaw axes. The counterbalance system helps offset the weight of laser optics and components, reducing vibrations and unwanted motion during laser operations. This enhances the overall performance, allowing for precise laser beam positioning, scanning, and tracking applications in fields such as laser marking, engraving, cutting, and material processing. The counterbalance system ensures smooth and stable laser operations for optimal results in the laser industry.

Specifications GXR 120

| GXR Series | GXR-120 | ||||

| Rotating Face diameter (mm) | 115 | ||||

| Position Accuracy Tilt & Yaw uncalibrated (arc sec) | ±20 | ||||

| Position Accuracy calibrated (arc sec) | ±2.5 | ||||

| Resolution System (arc sec) | 0.02 | ||||

| Repeatability Bi-directional (arc sec) | ±1.5 | ||||

| Max Axial Load (kg) | 18 | ||||

| Drive | Direct | ||||

| Error Axial Motion (um) | 2 | ||||

| Error Radial Motion (um) | 3 | ||||

| Max speed - Tilt (°/sec) (=/- °180) | 720 | ||||

| Max speed - Yaw (rpm) (endless) | 1150 | ||||

| Nominal Torque Tilt & Yaw (Nm) | 7.57 | ||||

| Stage Weight (kg) | 3.6 |

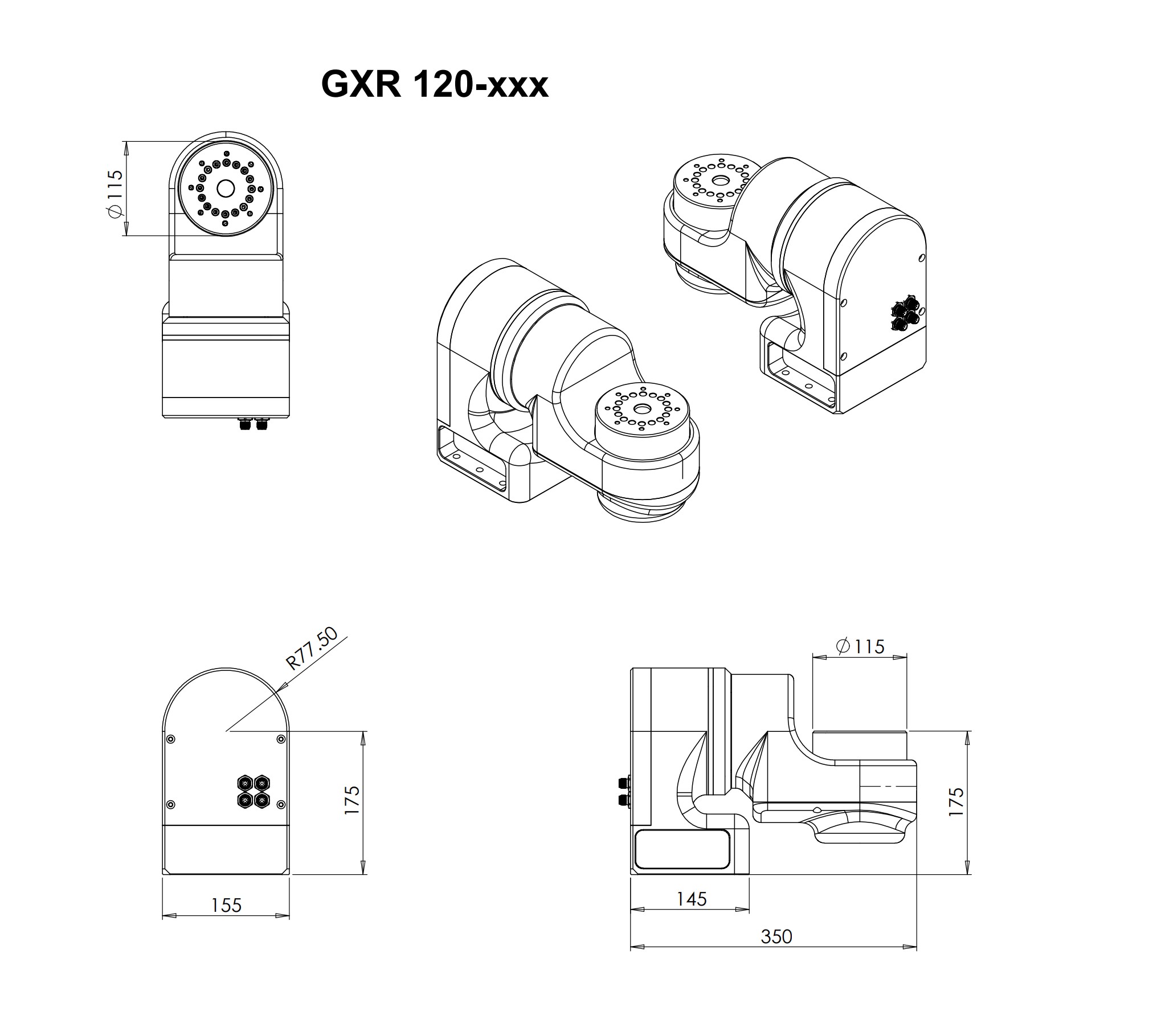

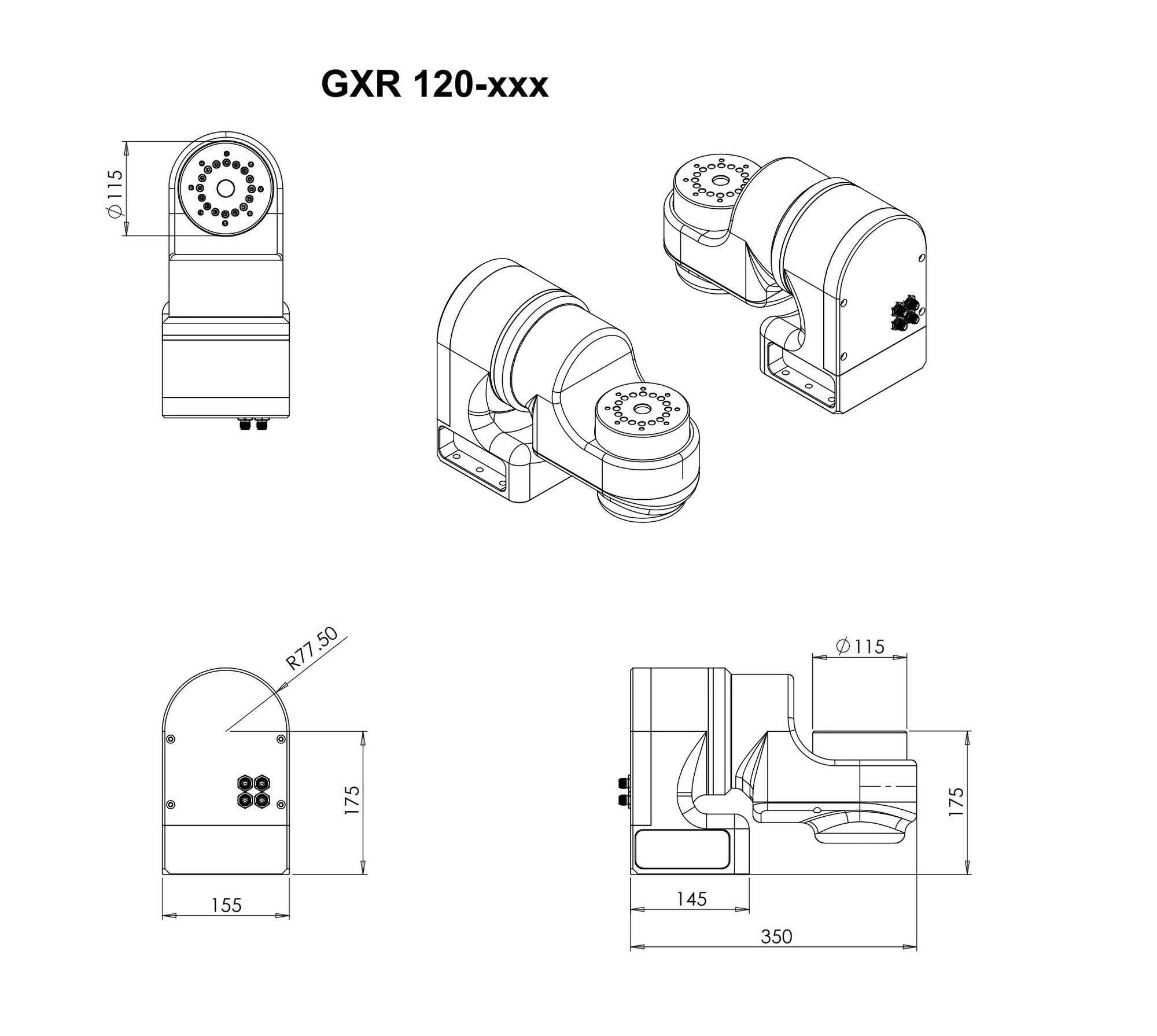

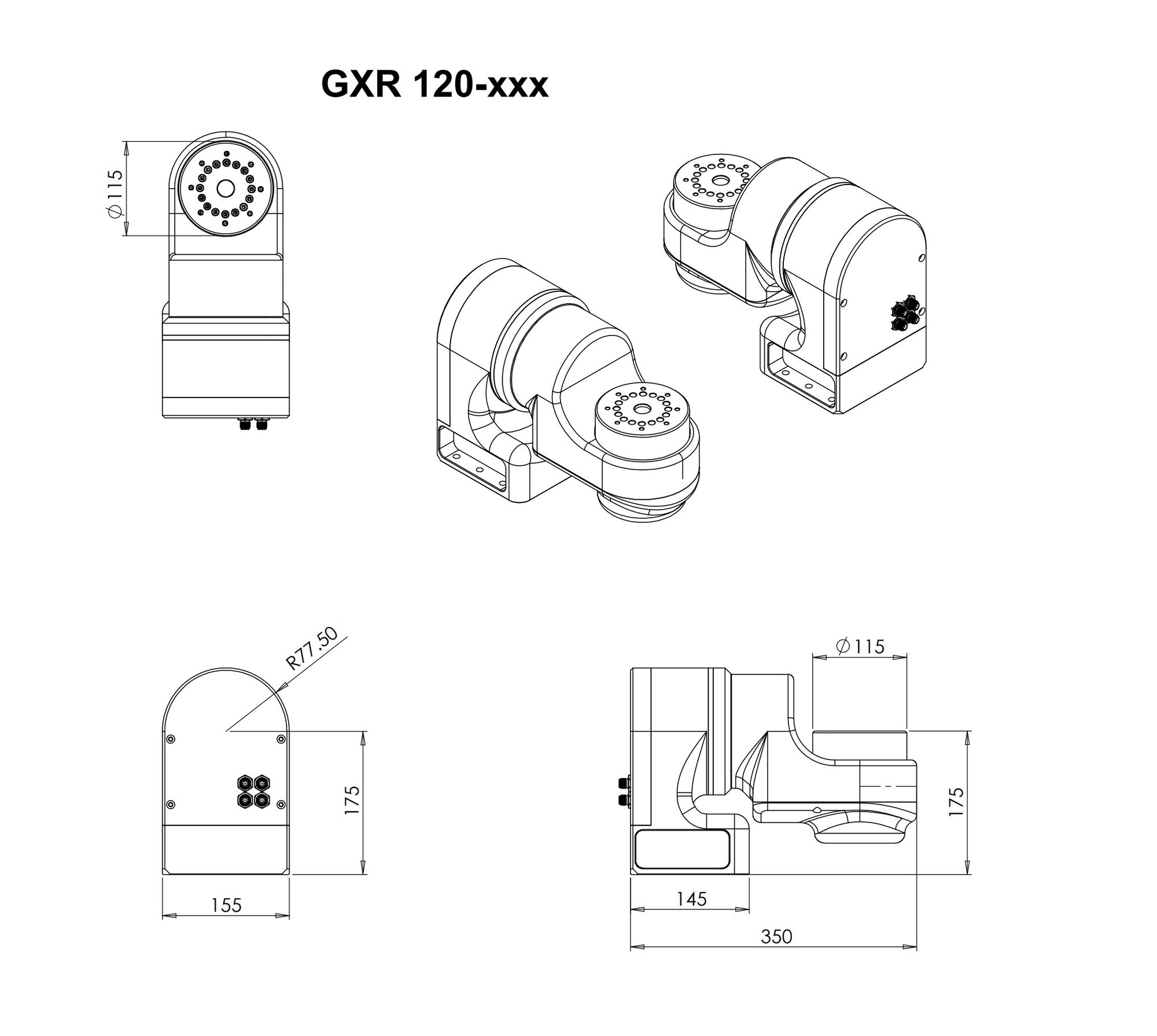

Product Dimensions

Ask An Engineer!

Quickly receive an answer to your question from a Gorman Dynamics engineer.

Related Products

- Direct drive rotary

- Load Capacity 26 kg

- Stiff high precision cross roller bearings

- High resolution absolute multi-turn rotary encoders

- Max speed - 1500 (rpm) (endless)

- Maximum torque 7.57 (Nm)

English

English

Español

Español

Français

Français

Deutsch

Deutsch

Svenska

Svenska

한국어

한국어

日本語

日本語