Custom Linear Stages

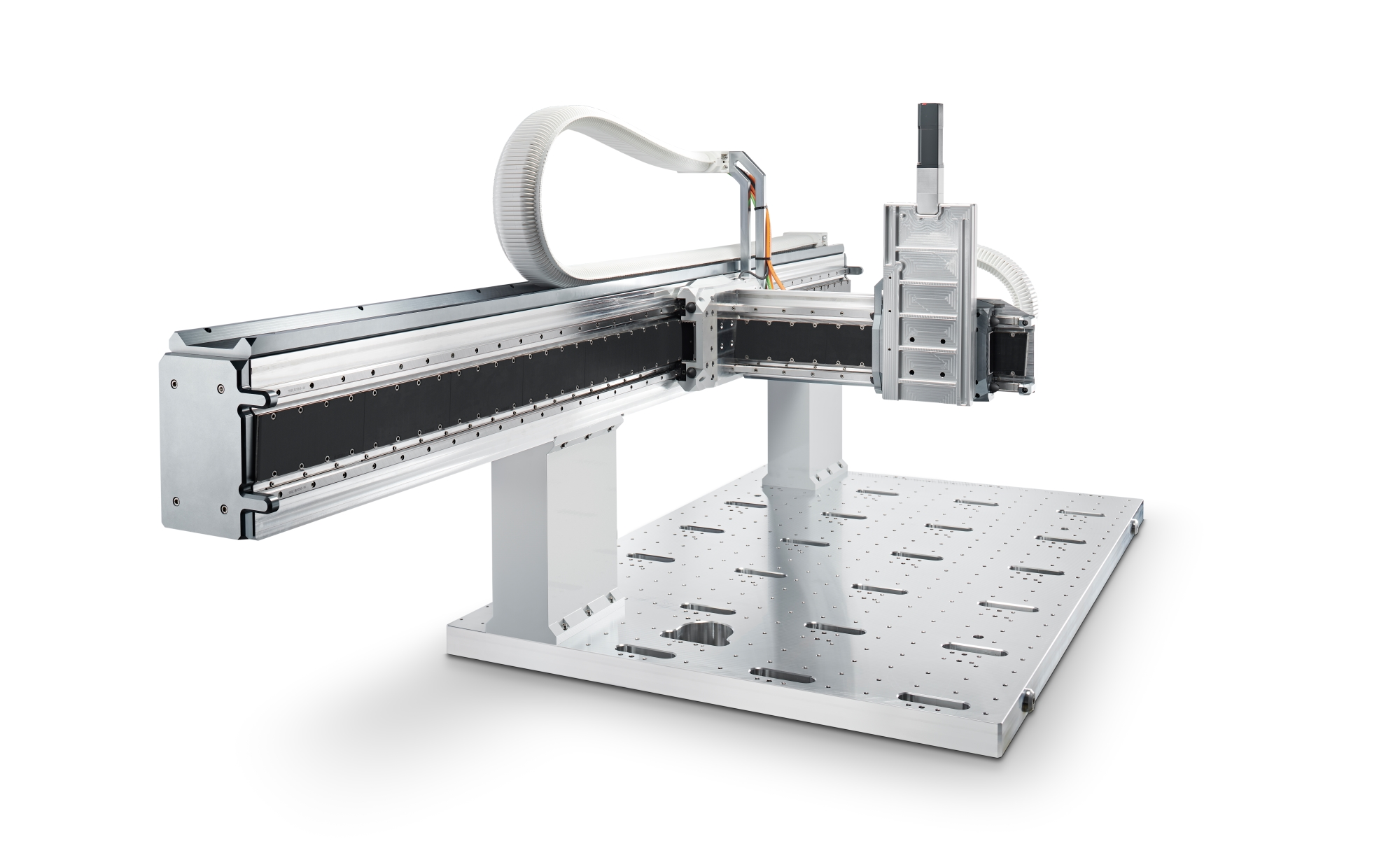

GH130 Heavy Duty Precision Gantry

- Travel up to 5700mm - Fixed X Axis

- Multi Gantries on X Axis

- Travel up to 2800mm - Moving Gantry Y Axis

- Multi Carriage Movers on Gantry Axis

- High Load Capacity per Carriage 225 kg, 2250 N

- Speed 3.5 m/s

- High resolution absolute linear encoder

- Iron Core Liner Motors

XYZ Precision Iron Core Stage Gantry - Laser Cladding

Large Precision Gantry Solutions

Gorman Dynamics specializes in large-scale precision gantry solutions featuring three-axis configurations (X, Y, and Z). These advanced gantries are designed to meet the demanding requirements of various industries, including Laser Metal Deposition (LMD) and 3D printing. They provide precise positioning and movement control in all three axes, enabling accurate and intricate additive manufacturing processes. With their exceptional accuracy and repeatability, Gorman Dynamics' gantry solutions deliver reliable and efficient performance for LMD and 3D printing applications. Whether for industrial manufacturing or research purposes, our gantry systems offer the precision and reliability needed for large-scale additive manufacturing.

Drive System - Iron Core Linear Motors

Utilizing iron core linear motors offers several advantages in motion control applications. Firstly, these motors provide high force density, allowing for powerful and dynamic performance. They deliver robust and consistent force, ensuring precise and reliable linear motion. Iron core linear motors also exhibit excellent acceleration and deceleration capabilities, enabling rapid and responsive movement. Additionally, they have a high degree of controllability, allowing for precise speed and position control. The absence of mechanical components like gears or belts reduces friction, resulting in smooth and efficient operation. Overall, the advantages of using iron core linear motors include enhanced performance, reliability, and flexibility in a wide range of industrial applications.

Tailored to Suite Your Application

At Gorman Dynamics, we understand the importance of tailoring our gantry solutions to meet the specific requirements of your application. Our gantries can be customized to accommodate various specialized features, such as the fitting of synchronized protective shutters for enhanced safety in laser applications. We can also incorporate mechanisms for end-of-arm tool changes, allowing for seamless interchangeability and versatility. Additionally, our gantries can be designed with appropriate guarding systems to suit the unique needs of the laser industry, ensuring optimal operator safety and equipment protection. Partner with us to receive a fully customized gantry solution that perfectly aligns with your specific application needs.

Benefits and Advantages

- High Payload Capacity: Gantries can handle significantly larger payloads compared to robots, making them suitable for heavy-duty applications that involve moving large objects or equipment.

- Extended Workspace: Gantries typically offer a larger working area or travel range, allowing for the handling of larger workpieces or the accommodation of multiple processes within a single setup.

- Stability and Precision: Gantries provide excellent stability and rigidity, enabling precise and accurate positioning with minimal deflection.

- This makes them ideal for applications that require high precision and repeatability.

- Customizability: Gantries can be easily customized and adapted to suit specific application requirements, such as integrating specialized end effectors, protective enclosures, or additional axes of motion.

- Scalability: Large-scale gantries can be easily scaled up or modified to accommodate future expansion or changes in production needs, providing long-term flexibility and adaptability.

- Cost-Effective Solution: In certain scenarios, large-scale gantries can offer a more cost-effective solution compared to robots, especially when handling heavy loads or covering larger work areas.

Overall, large-scale gantries excel in applications that demand high payload capacity, extended workspace, stability, and precision, providing a reliable and efficient solution for a wide range of industrial processes.

Application - Large precision gantries offer versatile use cases across various industries

- Aerospace Manufacturing: Large precision gantries are used for assembling and machining large aircraft components, such as wings or fuselages. The gantries enable precise positioning, drilling, and milling operations, ensuring accurate and efficient production.

- Automotive Industry: Gantries find application in automotive manufacturing processes, including body-in-white assembly, where they handle the precise placement and welding of vehicle body components. They also facilitate the inspection and alignment of large automotive parts.

- Semiconductor Manufacturing: Large precision gantries are utilized in semiconductor production for wafer handling, inspection, and testing processes. They ensure accurate positioning and movement of wafers throughout various stages of manufacturing.

- Heavy Equipment Manufacturing: Gantries are employed in the production of heavy machinery, such as construction equipment or industrial machinery. They enable precise machining, welding, and assembly of large-scale components.

- Packaging and Logistics: Gantries play a vital role in automated packaging and logistics systems, where they assist in picking, placing, and sorting objects with precision. They ensure efficient and reliable movement of goods in high-volume production or distribution environments.

- Medical Device Manufacturing: Gantries are utilized in the production of medical devices, such as prosthetics or imaging equipment. They aid in precise assembly, testing, and quality control processes, ensuring compliance with strict industry standards.

- Robotics and Automation: Large precision gantries serve as fundamental components in robotics and automation systems, providing the necessary movement and positioning capabilities for various applications, including material handling, inspection, and assembly.

- EHLA Manufacturing: Large precision gantries are crucial for EHLA applications, enabling the precise control of laser beam and deposition head movement. This facilitates the rapid and precise deposition of material layers, resulting in efficient and high-quality production.

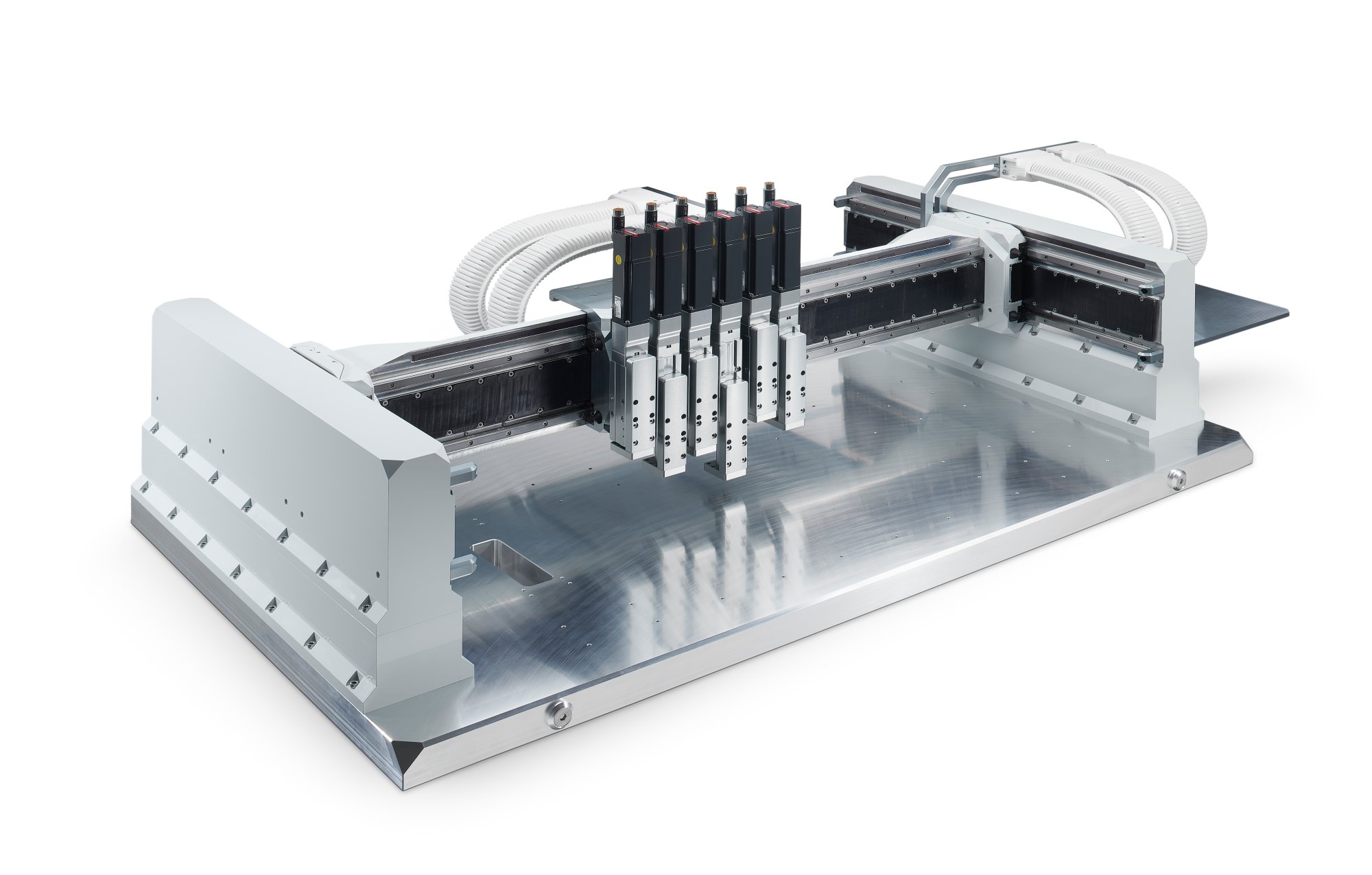

Related Products

- Travel 200mm to 1600mm - Fixed X Axis

- Multi Gantries on X Axis

- Travel 200mm to 600mm - Moving Gantry Y Axis

- Multi Carriage Movers on Gantry Axis

- High Load Capacity per Carriage 25 kg, 250 N

- Speed 4 m/s

- High resolution absolute linear encoder

- Iron Core Liner Motors

- 300mm to 1400mm - Fixed Y Axis

- Multi Gantries on Y Axis

- 2 Motors per moving Gantry

- 300mm to 1400mm - Moving X Axis

- Multi Carriage Movers on Gantry Axis

- High Load Capacity 35 kg, 350 N

- Speed 3 m/s

- High resolution absolute linear encoder

- Iron Core Liner Motors

Ask An Engineer!

Quickly receive an answer to your question from a Gorman Dynamics engineer.

English

English

Español

Español

Français

Français

Deutsch

Deutsch

Svenska

Svenska

한국어

한국어

日本語

日本語